Extending HIGmill Liner Life with REMALOX Ceramic Wear Protection

A leading Australian mining operation faced repeated issues with their HIGmill, where standard rubber wear liners were failing to last until the next scheduled shutdown. This led to unplanned maintenance, increased operational costs, and production disruptions.

CHALLENGE

- Standard rubber liners wearing prematurely.

- Unplanned shutdowns impacting production schedules.

- Rising maintenance costs and increased downtime risks.

SOLUTION

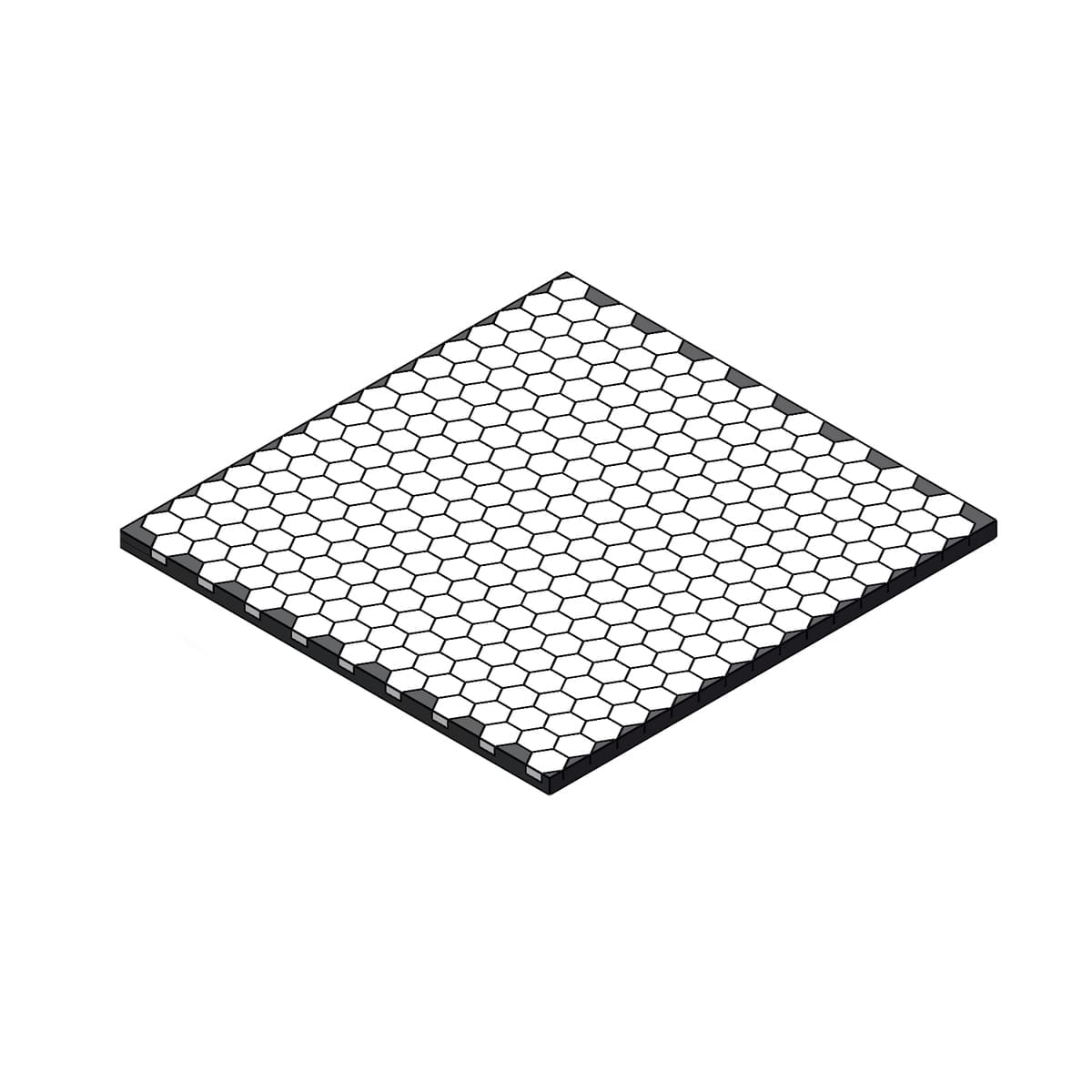

REMA TIP TOP recommended the use of REMALOX, a high-performance ceramic wear protection system. REMALOX is designed for severe abrasion and impact applications, offering:

- High abrasion resistance for significantly longer service life.

- Superior impact strength, protecting against demanding HIGmill operating conditions.

- Reduced maintenance needs, with extended intervals between shutdowns.

KEY METRICS

- During a planned shutdown, REMA TIP TOP’s service team:

- Removed the worn rubber liners.

- Sandblasted the mill lining surface to prepare it.

- Installed and applied REMALOX on-site, ensuring a durable and long-lasting finish.

OUTCOME

- Elimination of unplanned maintenance due to liner failure.

- Extended service life of liners, increasing asset reliability.

- Reduced downtime and maintenance costs.

- Improved operational confidence with a proven wear protection solution.

Learn more about how REMALOX can extend the life of your assets.

Explore REMALOX

INTERNATIONAL

INTERNATIONAL