Maintenance Strategy Develpoment

Reliability charters, Consequence of Failure Analysis (COFA/FMECA), preventative maintenance strategies and inspection templates.

We partner with our customers to deliver innovative preventative maintenance using advanced analytics, technologies and fixed-fee service guarantees. Our range of innovative hardware and software solutions gather and analyse asset performance, providing valuable data for improved asset management.

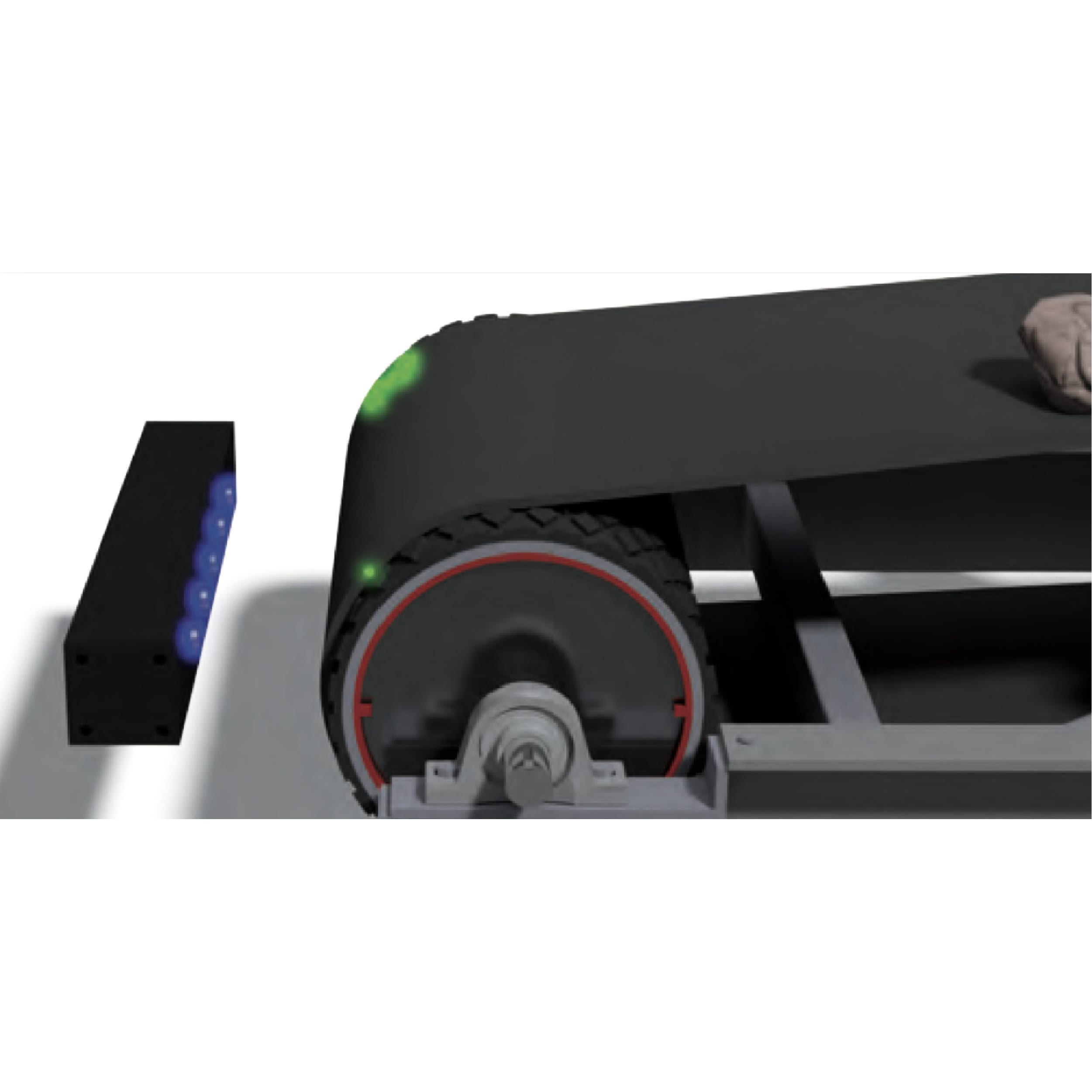

The Loopless Rip Detection System leverages advanced technology to provide real-time monitoring and rapid detection of conveyor belt rips. With no need for embedded sensors, it offers a maintenance-free solution designed to minimise downtime, reduce costs, and improve operational efficiency.

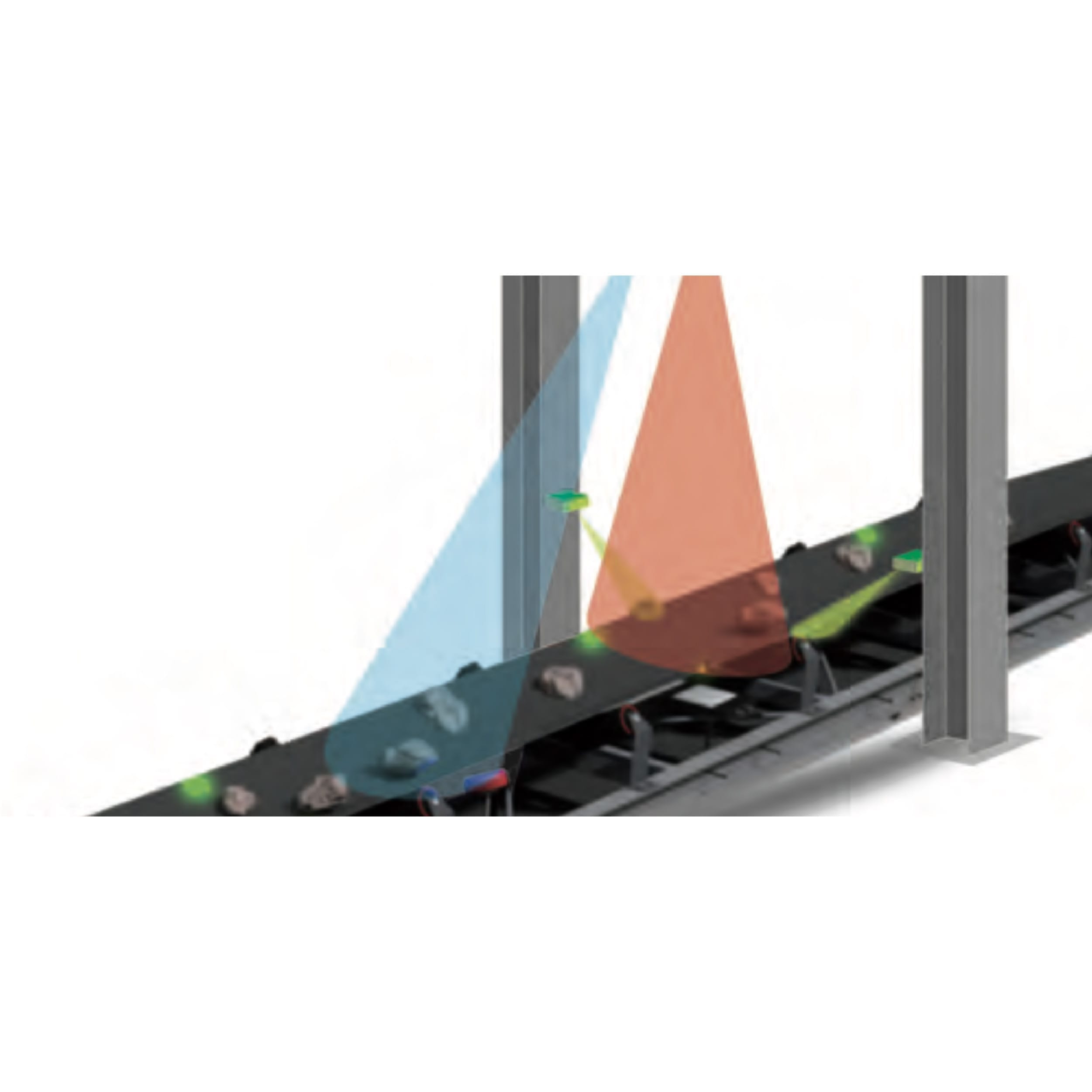

LEARN MOREThe Automated Roller Failure Detection System uses advanced Distributed Fiber Optic Sensing (DFOS) technology to provide real-time monitoring of conveyor systems. Designed to detect early-stage failures and minimise downtime, this innovative solution enhances safety, efficiency, and operational performance across industries.

LEARN MORE

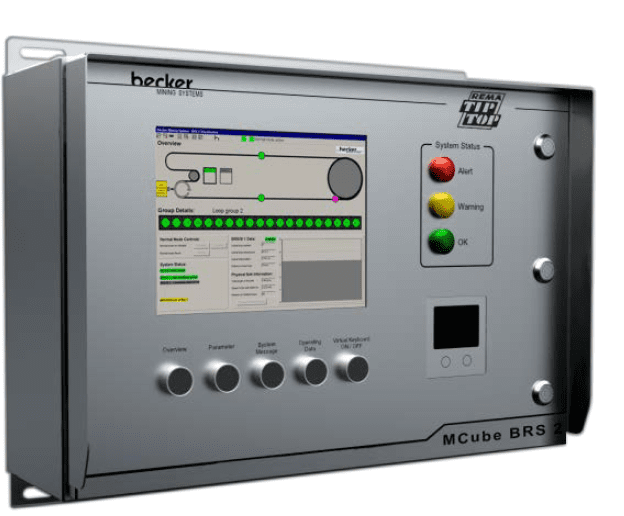

There is a growing expectation from plant operators around Australia to create Smart Plants that allow for digital monitoring and management. Innovative technology solutions such as belt rip detection, belt thickness monitoring, scanning and sensors, provided by MCube, can be used to provide plant operators with greater insight into the current status of their conveyor belts by providing real-time data showing any forms of damage.

Get the best understanding of your conveyor belt with our MCube Steel Cord Scan System that provides accurate, reliable and immediate detection of damaged cables and splice cord condition.

LEARN MORE

The Belt Thickness Monitoring System (BTM) continuously measures wear and wear characteristics on conveyor belts by use of ultrasonic sound-waves, generating over 1.000 readings per second in order to present an accurate graphical representation of the conveyor belt.

LEARN MORE

The Becker Mining BRS-2 Rip Detection System uses advanced technology to detect conveyor belt rips in real time, preventing damage and reducing downtime.

LEARN MORE

MCube Radar Based Sensor Systems allow for the detection of volumes and masses on conveyor belts for improved throughput.

LEARN MORECloud-based software solutions, provided by CCube, allow for efficient management, analysis and reporting of data for controlled maintenance workflows for equipment, whilst providing real time reporting and planning of maintenance and inspection activities, all while minimising unplanned downtime.

LEARN MORE

Total Conveyor Maintenance means treating your conveyor as an integrated system. Our unique asset management approach, CARMA, pairs analysts, engineers, maintenance and product specialists to deliver cost effective, data driven recommendations designed to reduce your costs and increase your availability.

Reliability charters, Consequence of Failure Analysis (COFA/FMECA), preventative maintenance strategies and inspection templates.

Steel cord scanners, belt thickness monitoring systems, rip detection systems, Internet of Things (IoT) devices, digital forms, Field Service Management, analysis and reporting platforms.

Asset performance, lifecycle analysis, expenditure analysis, asset availability & reliability, contract performance, machine learning, abnormality detection and artificial intelligence.

"*" indicates required fields