MCube Steel Cord Scan System (SCS)

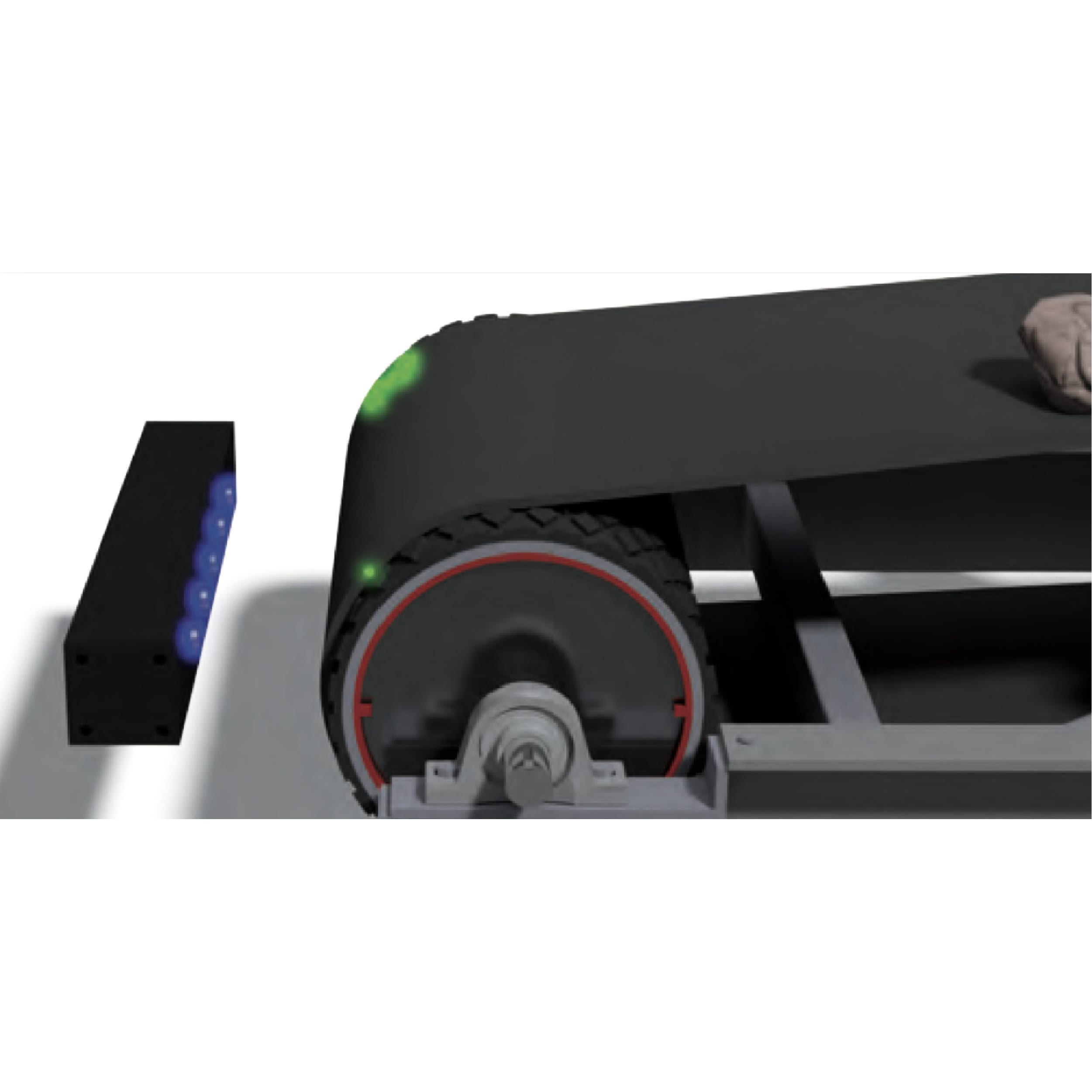

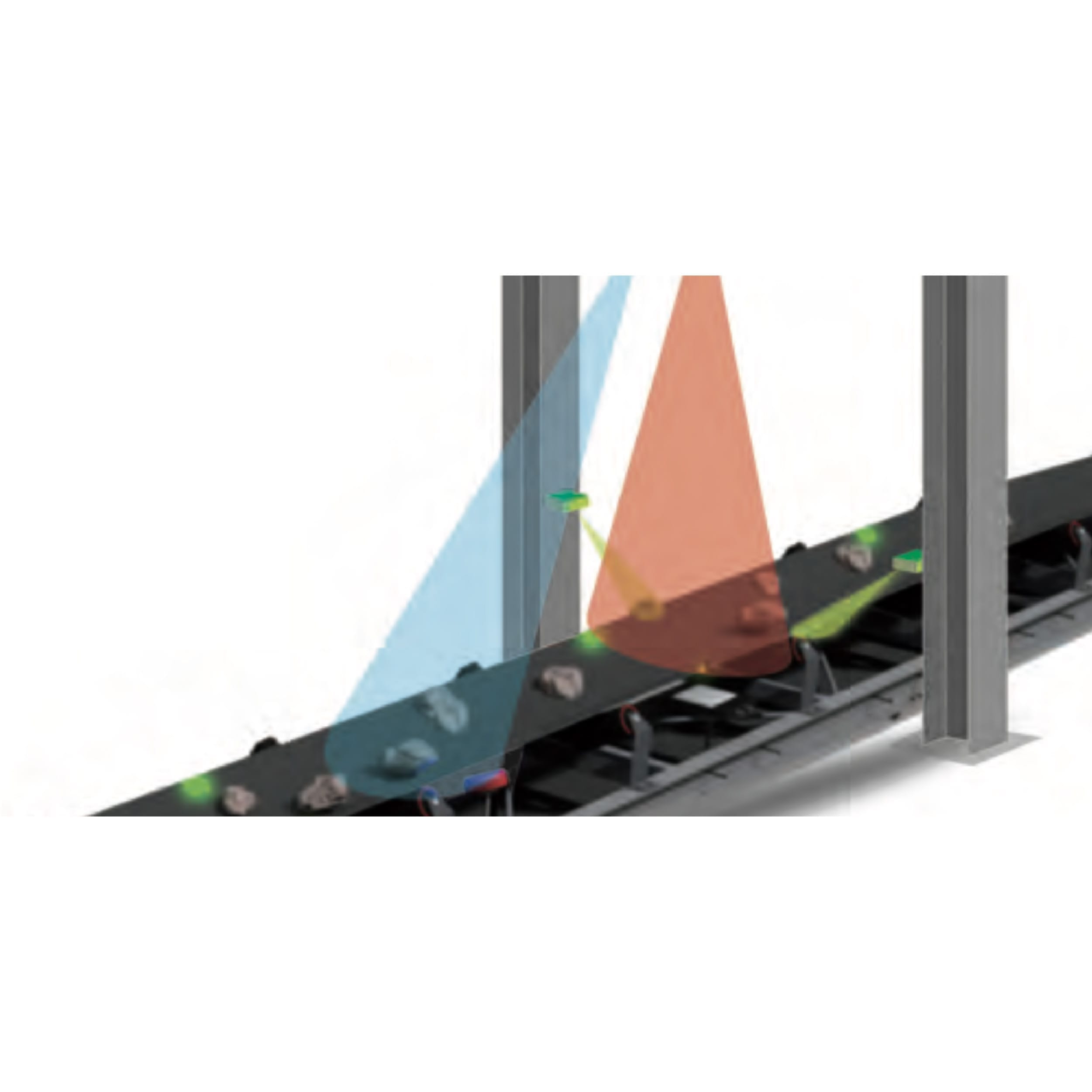

Get the best understanding of your conveyor belt with our MCube Steel Cord Scan System that provides accurate, reliable and immediate detection of damaged cables and splice cord condition. The Steel Cords in your conveyor belts are integral to the safe operation of the conveyor system. Yet, they are covered in rubber, making it difficult if not impossible to visually assess their condition. Hidden within the rubber, the Steel Cords are smashed during material loading, fatigued from continual bending, damaged when the belt drifts into structure and corroded from water ingress. In such events where the cords are damaged or broken, the tension is spread to the remaining cords. Left unchecked those remaining cords are more likely to break, leading towards a potential catastrophic belt tear. From a reliability and risk mitigation standpoint, it is imperative to inspect Steel Cords within belting. REMA TIP TOP offer this service with our proprietary state of the art MCube Steel Cord Scan (SCS) System. With unparalleled resolution, the MCube SCS will detect even single cord damage and for every damage event estimate the number of cords affected. It delivers immediate results to the technician who can then inspect or alert you to any critical faults on the day. A final report provides recommendations on managing the damage. Additionally, the MCube SCS automatically identifies the splices in the belt and produces a belt map. The technician will check for splice integrity from the resulting images. REMA TIP TOP offers this service as a once off check, as a routine maintenance inspection, or even as a permanent continuous monitoring system. Get in touch with us to discuss what strategy suits your needs.

INTERNATIONAL

INTERNATIONAL