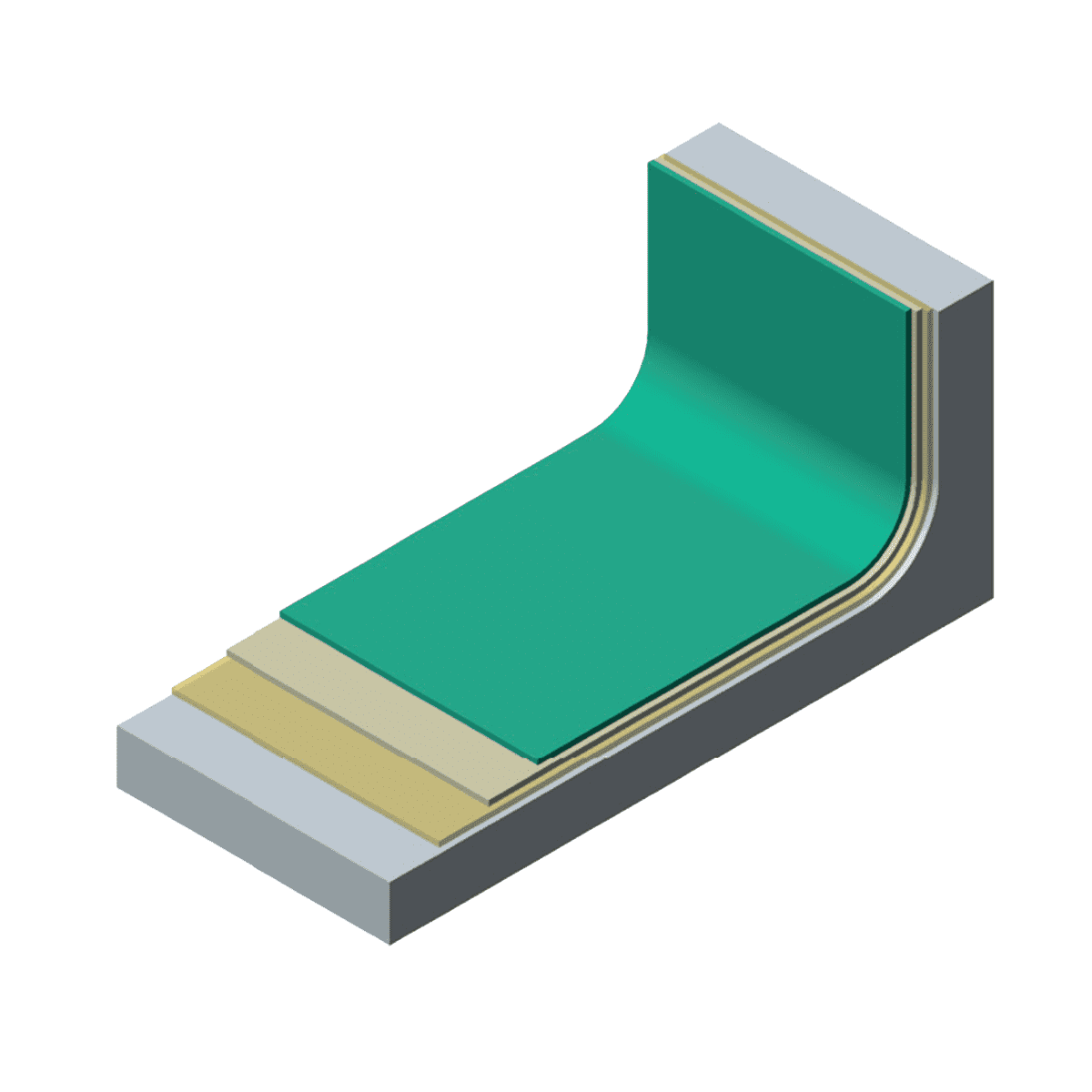

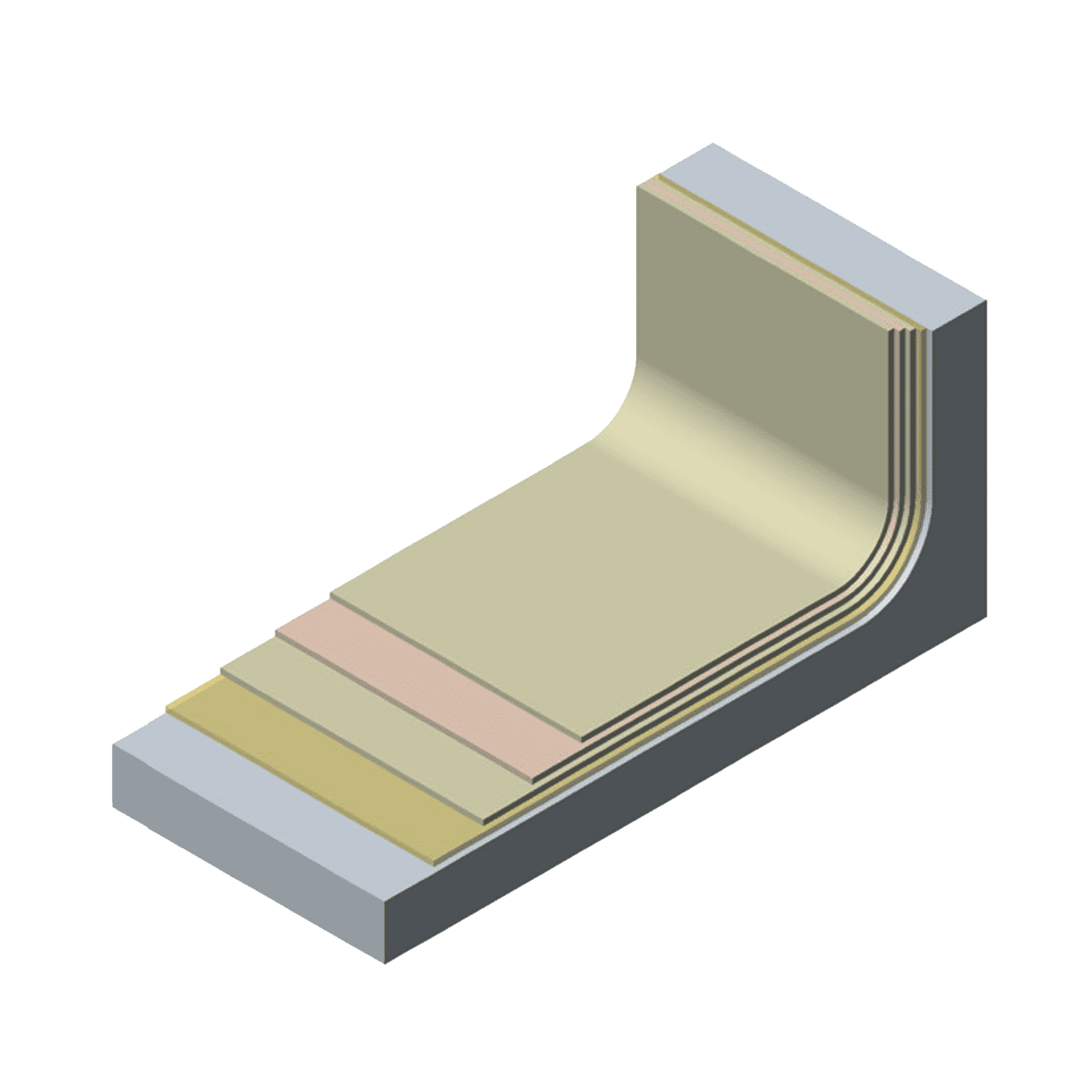

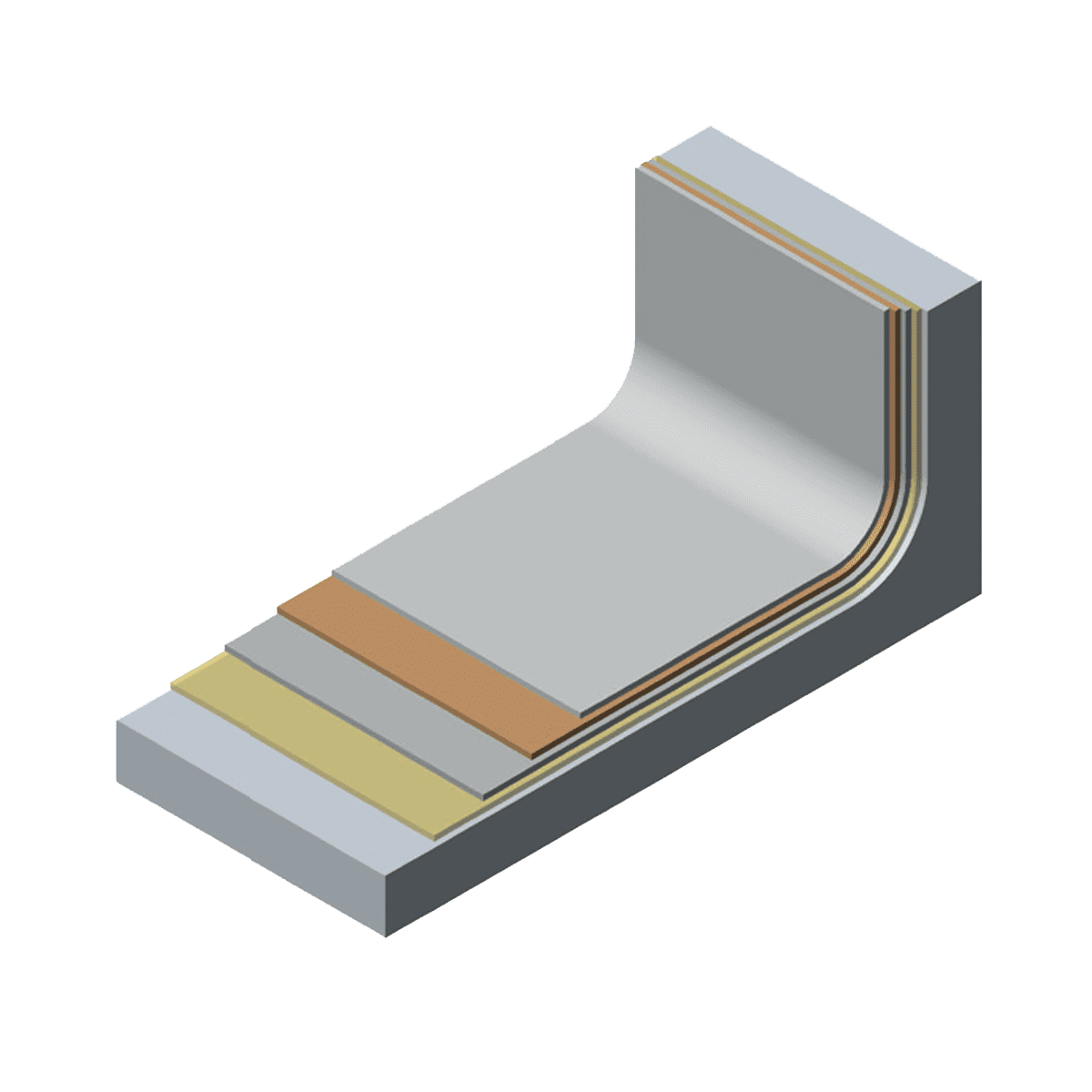

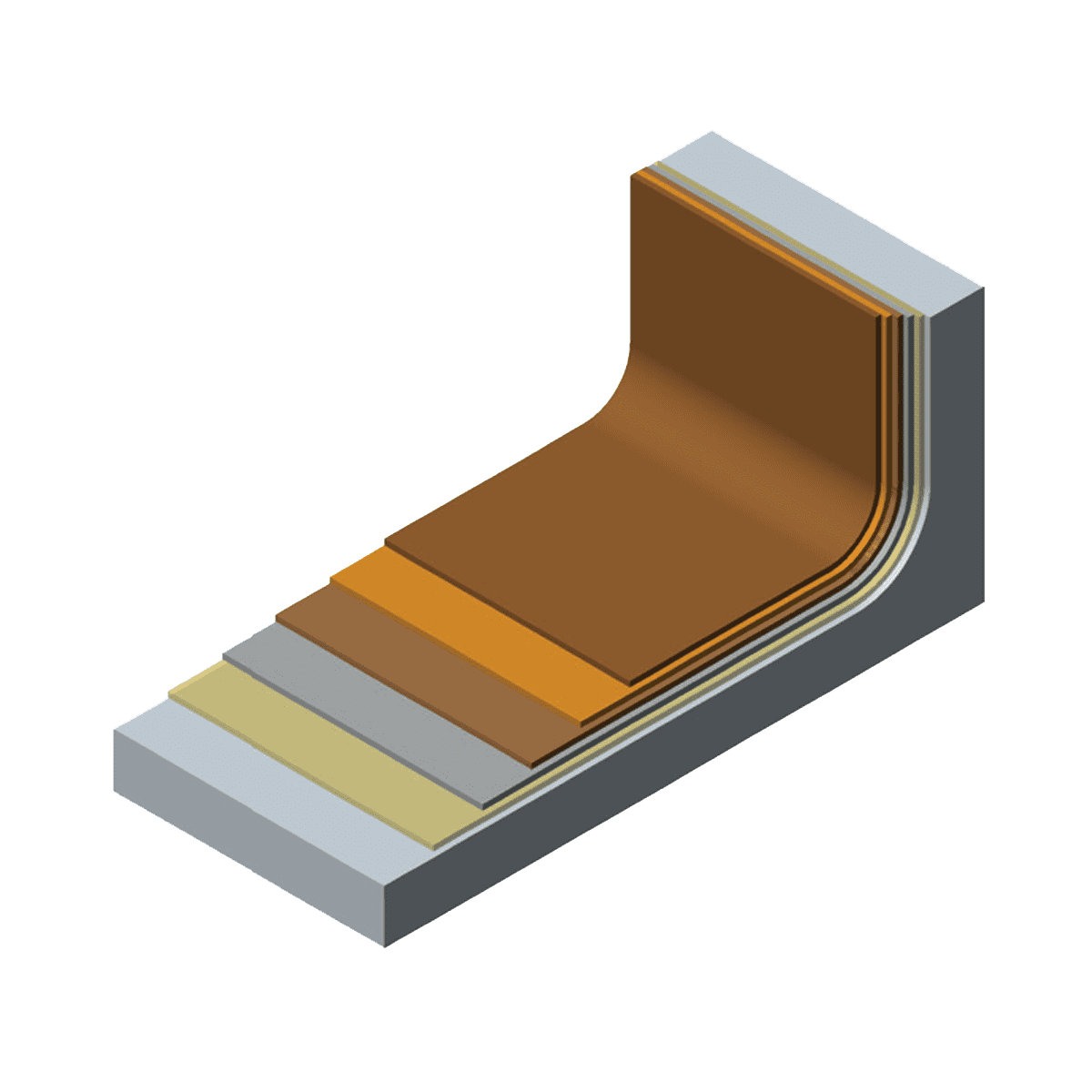

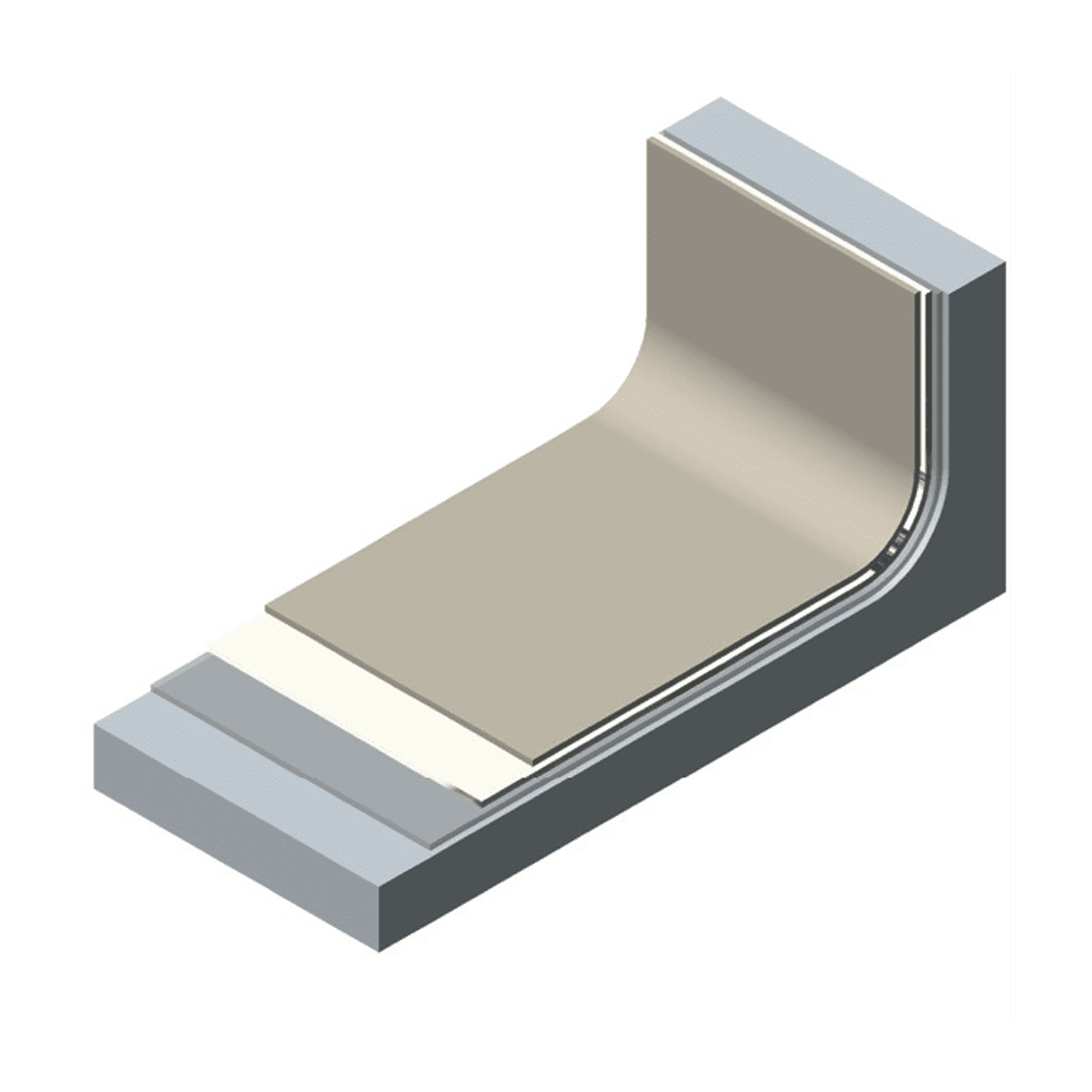

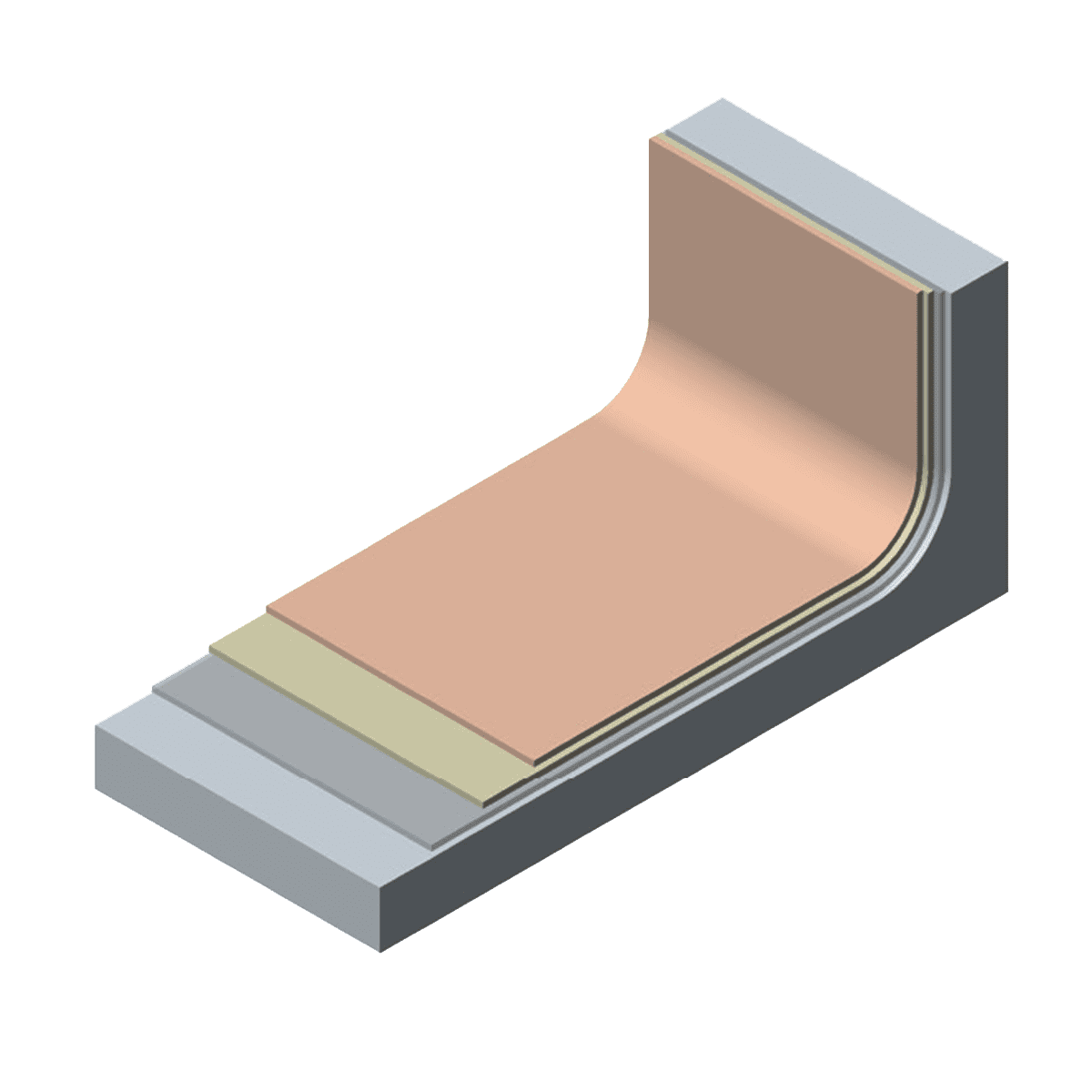

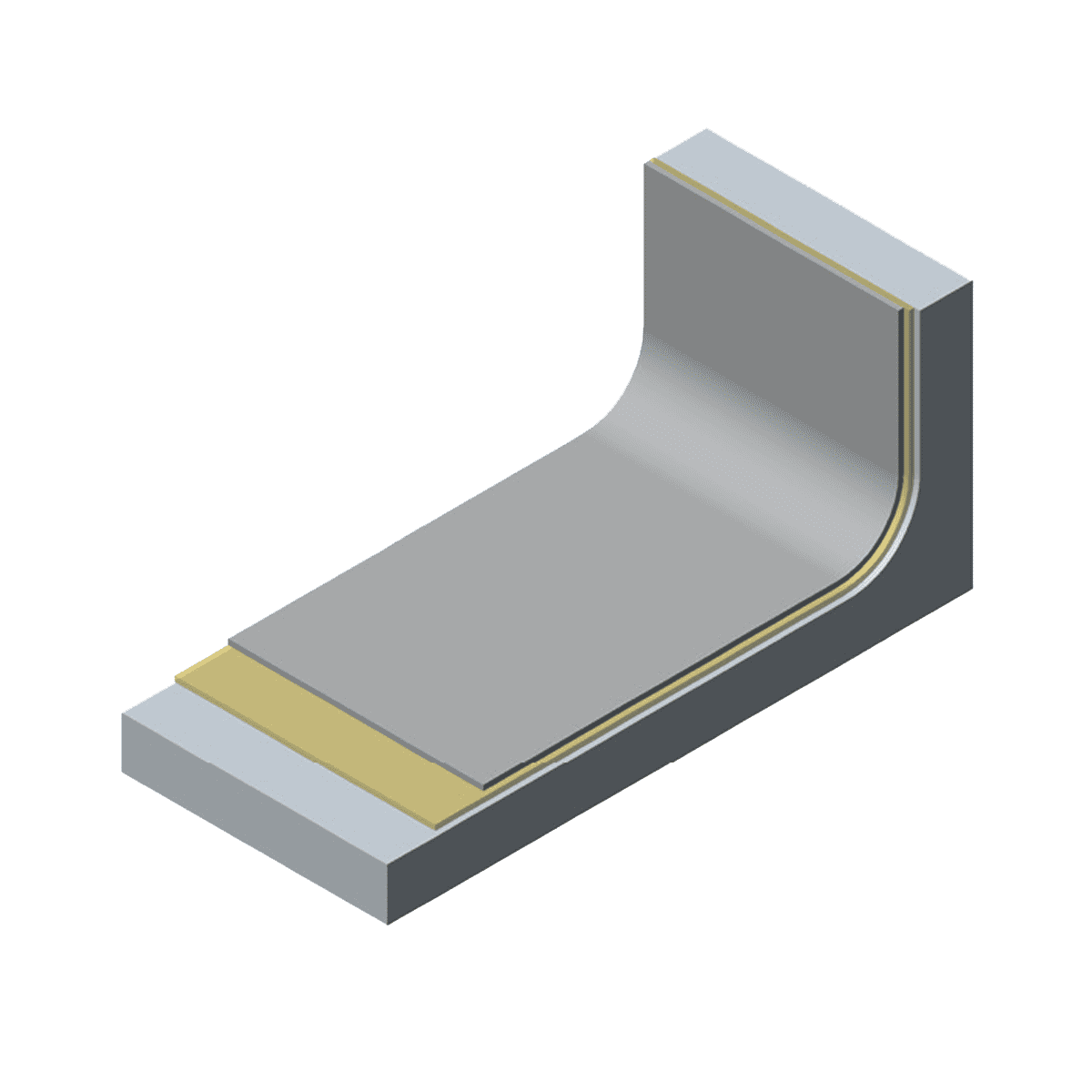

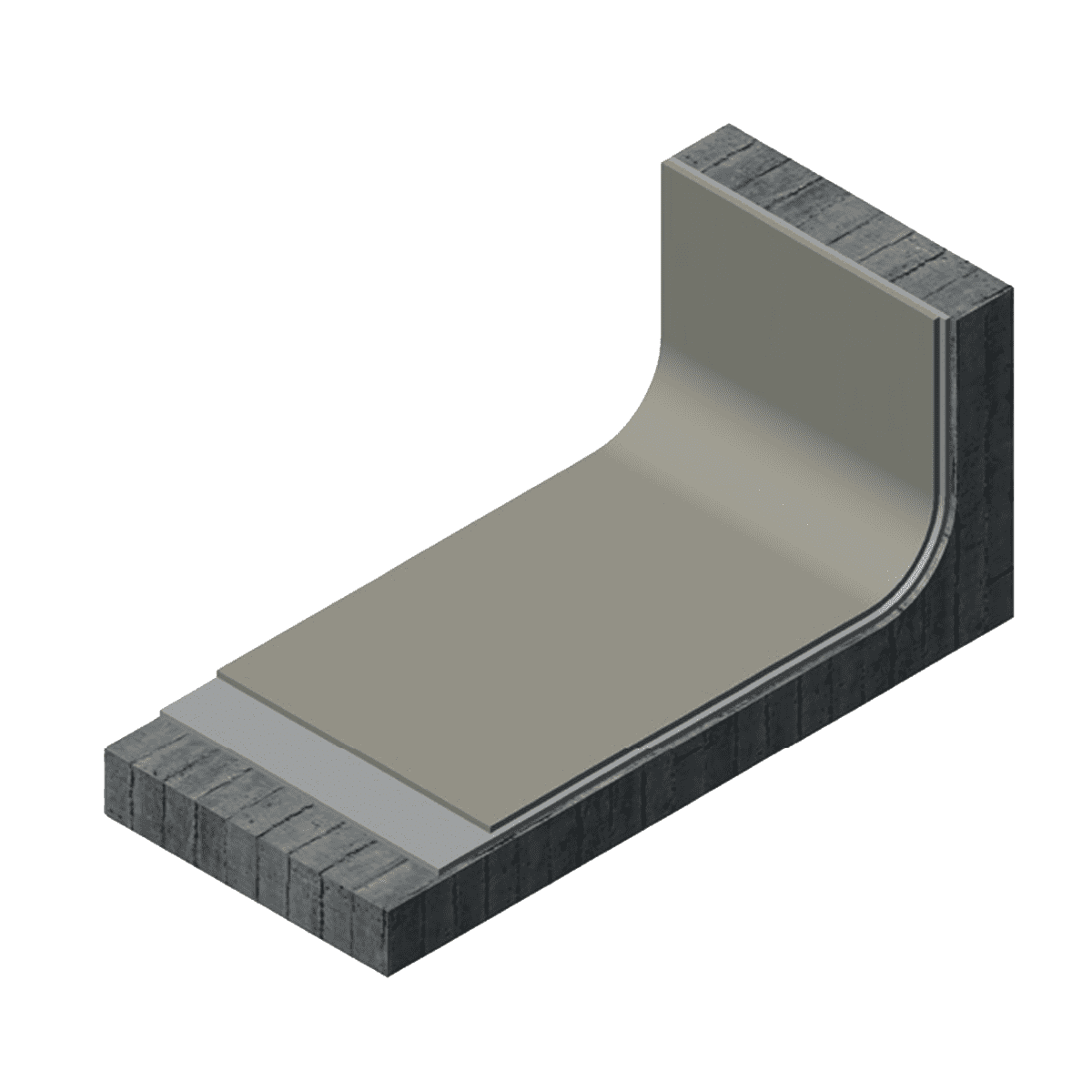

COROFLAKE

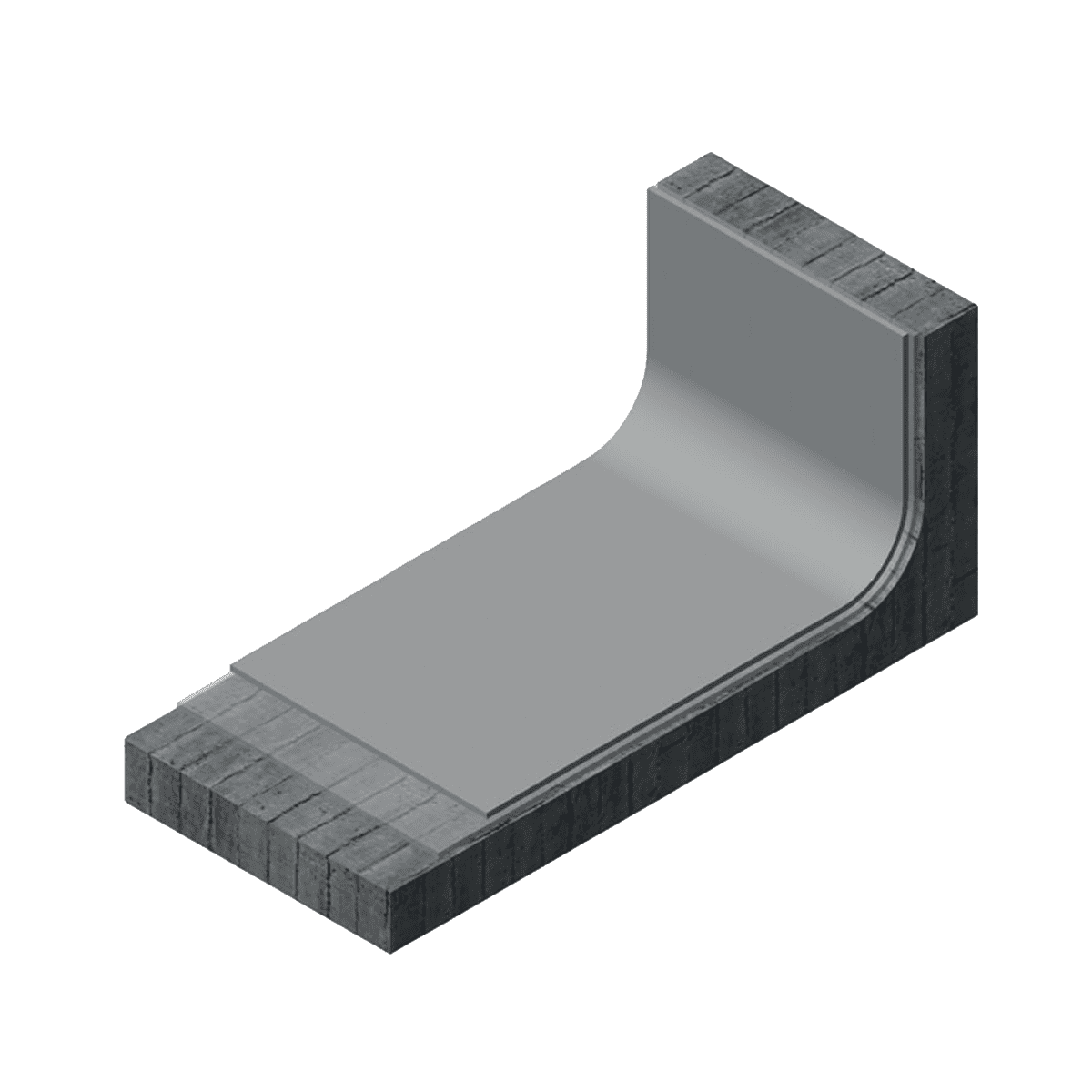

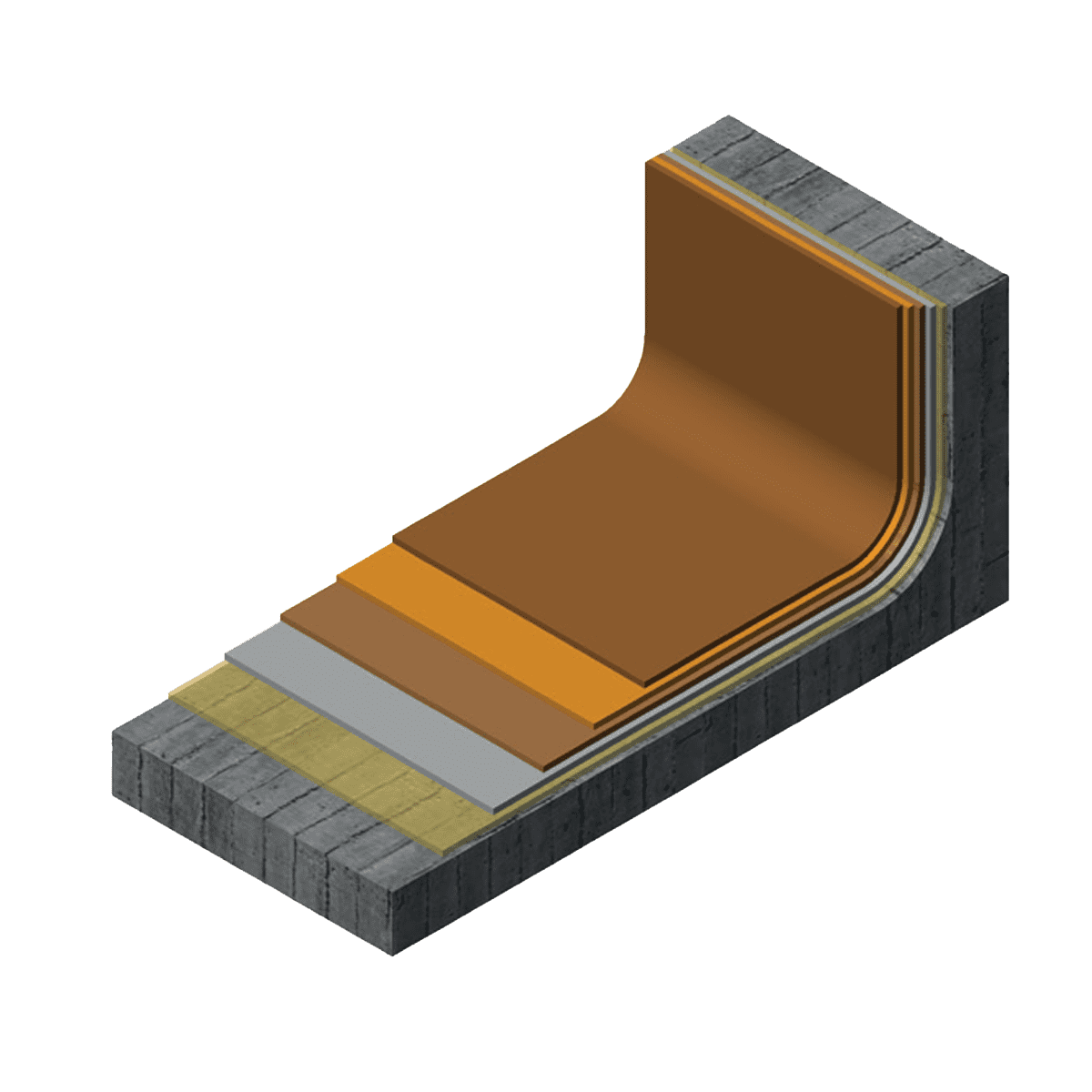

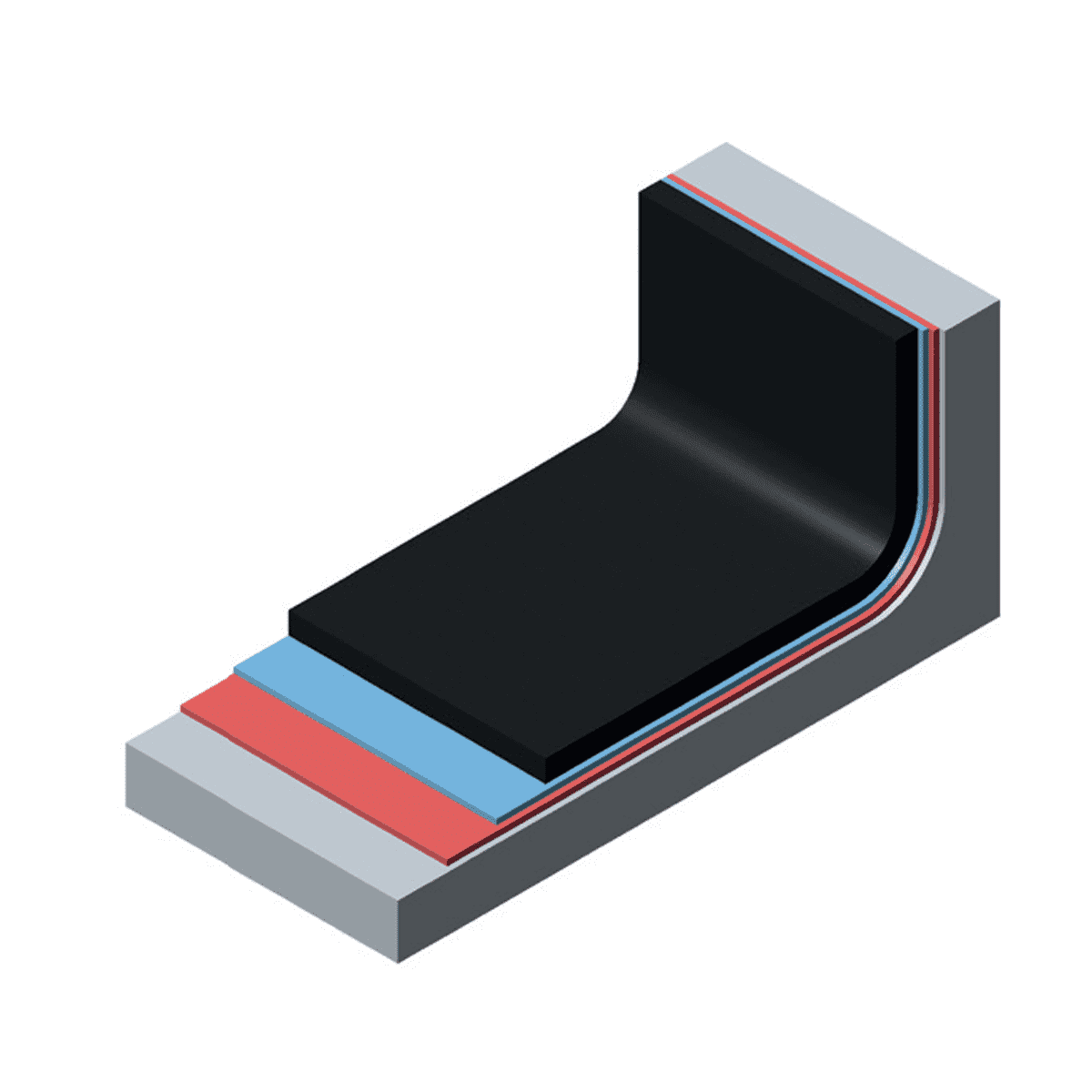

The COROFLAKE systems applied with trowel are coatings for the protection of metal- lic parts from aggressive media under permanent wet immersion. They are based on polyester and vinyl ester resins and are strengthened with micro-thin C-glass flakes. The resins used offer outstanding protection against chemicals, while the glass flakes, which are aligned parallel to the substrate, offer excellent permeation resistance. A nominal thickness of 2.0 mm is achieved with only two layers. These COROFLAKE troweled coatings can be used up to a wet temperature of 90 °C.

INTERNATIONAL

INTERNATIONAL