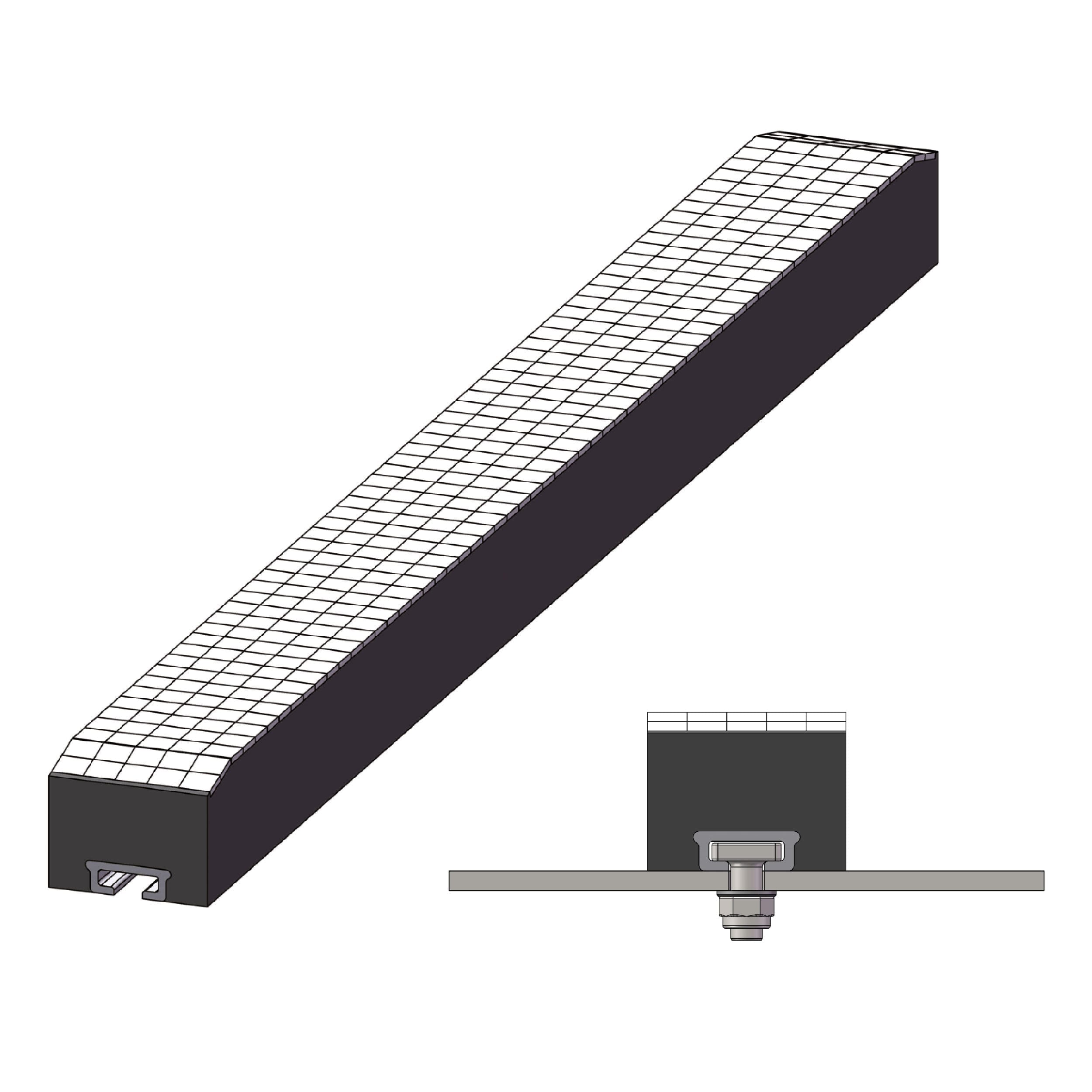

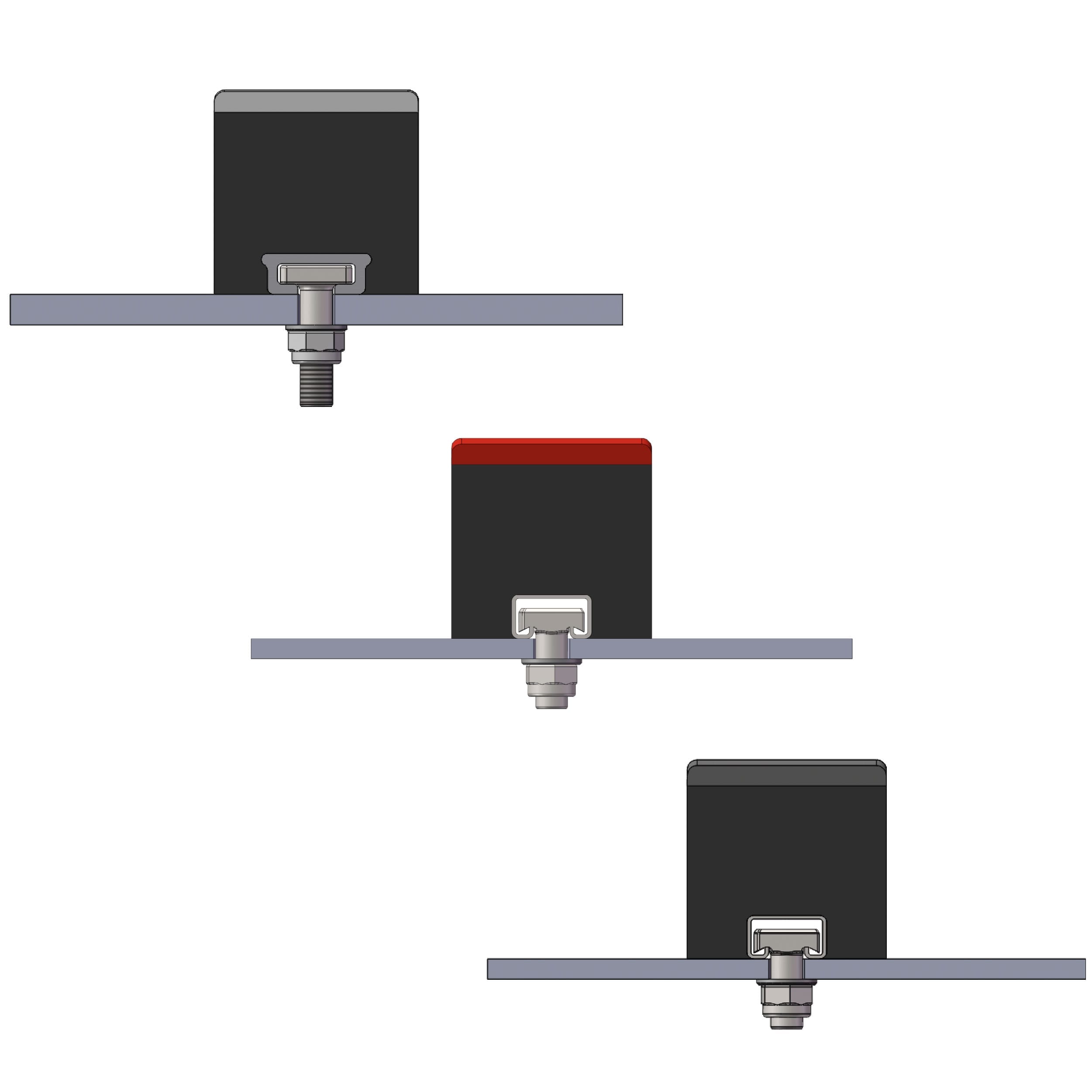

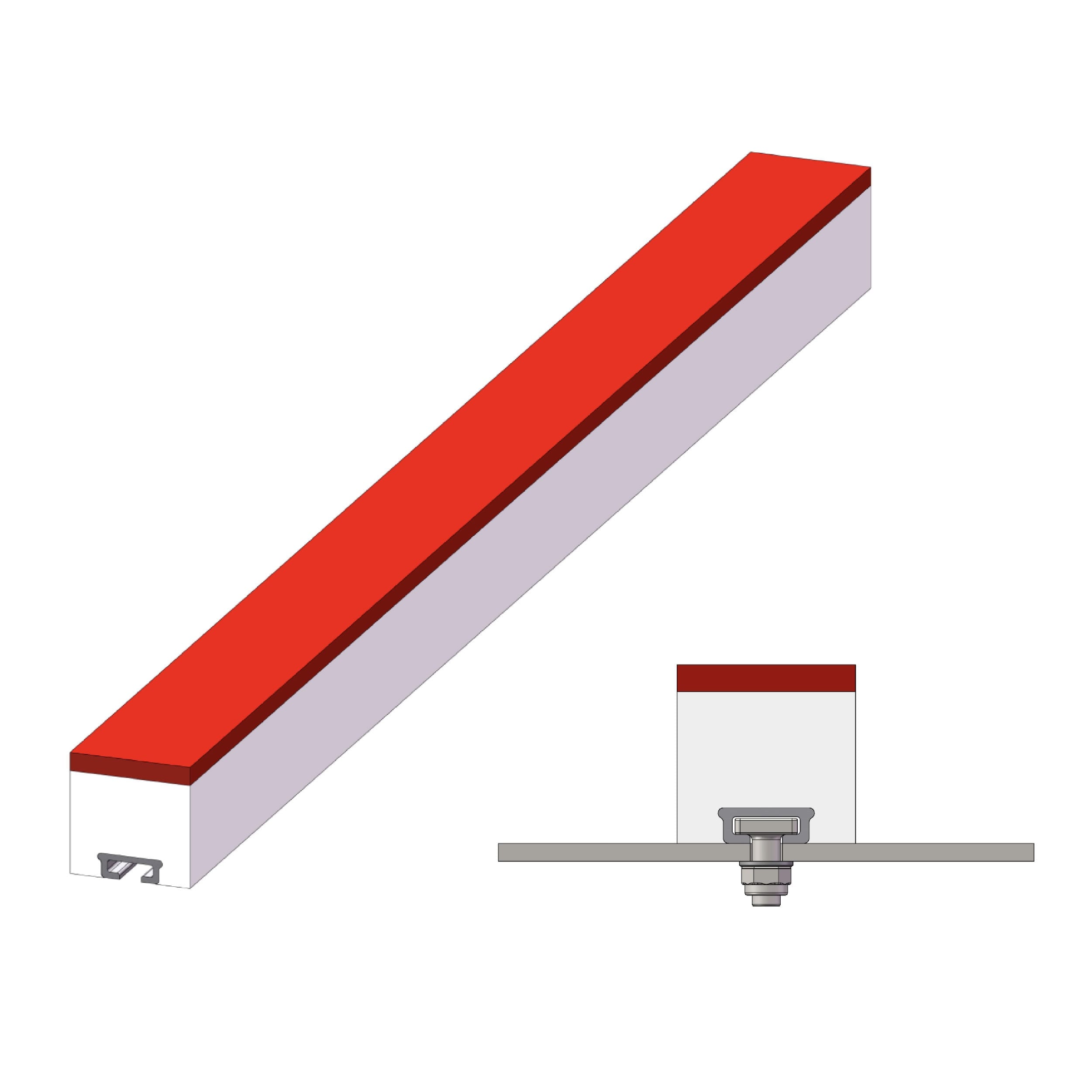

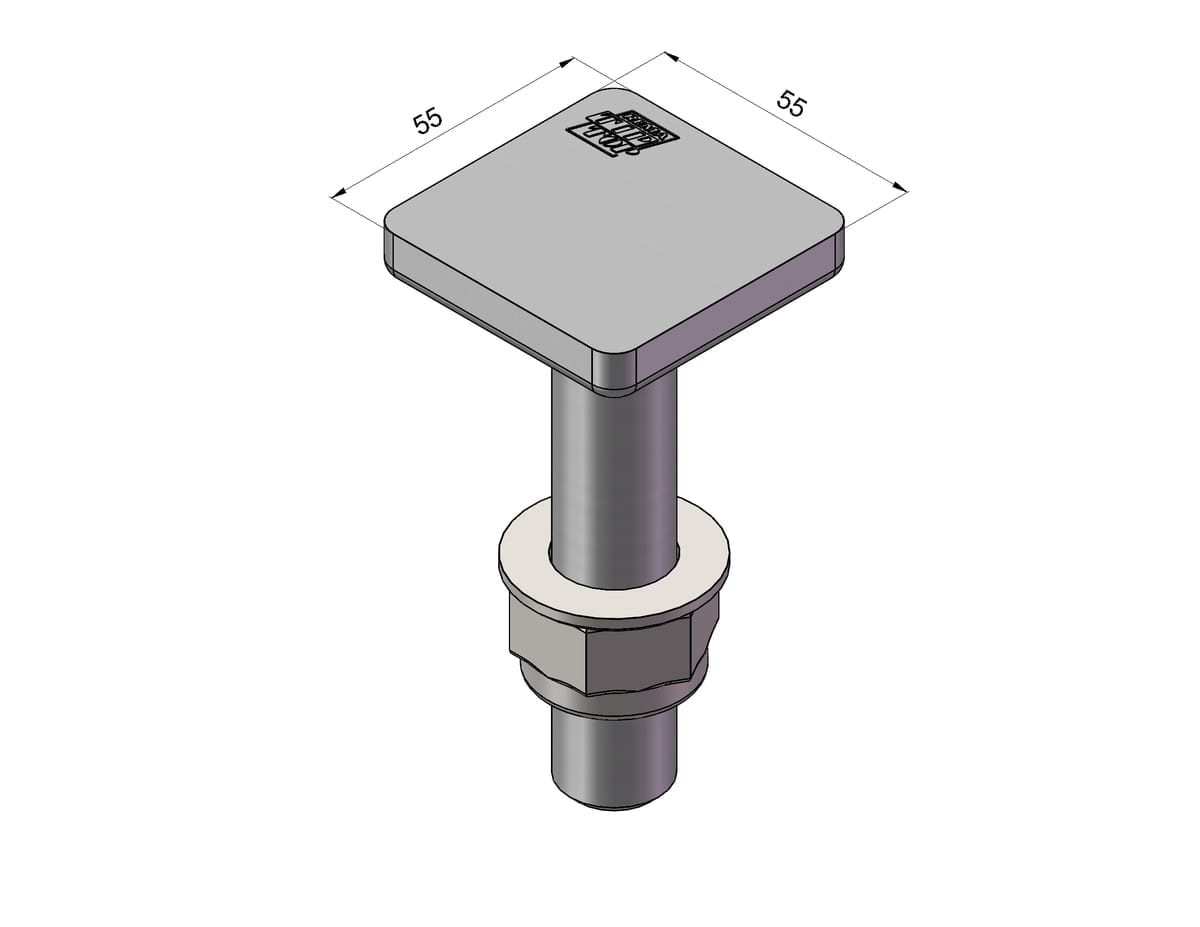

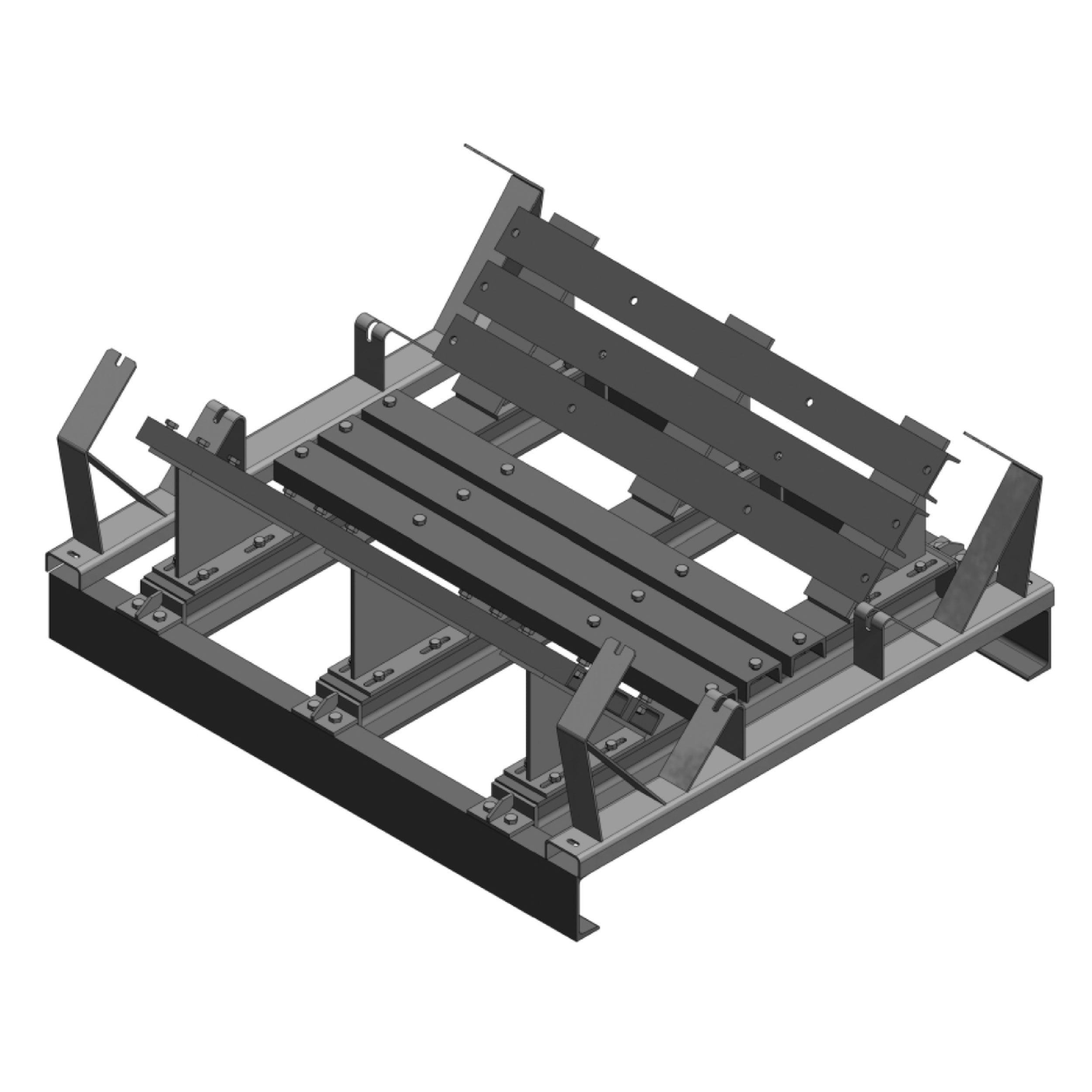

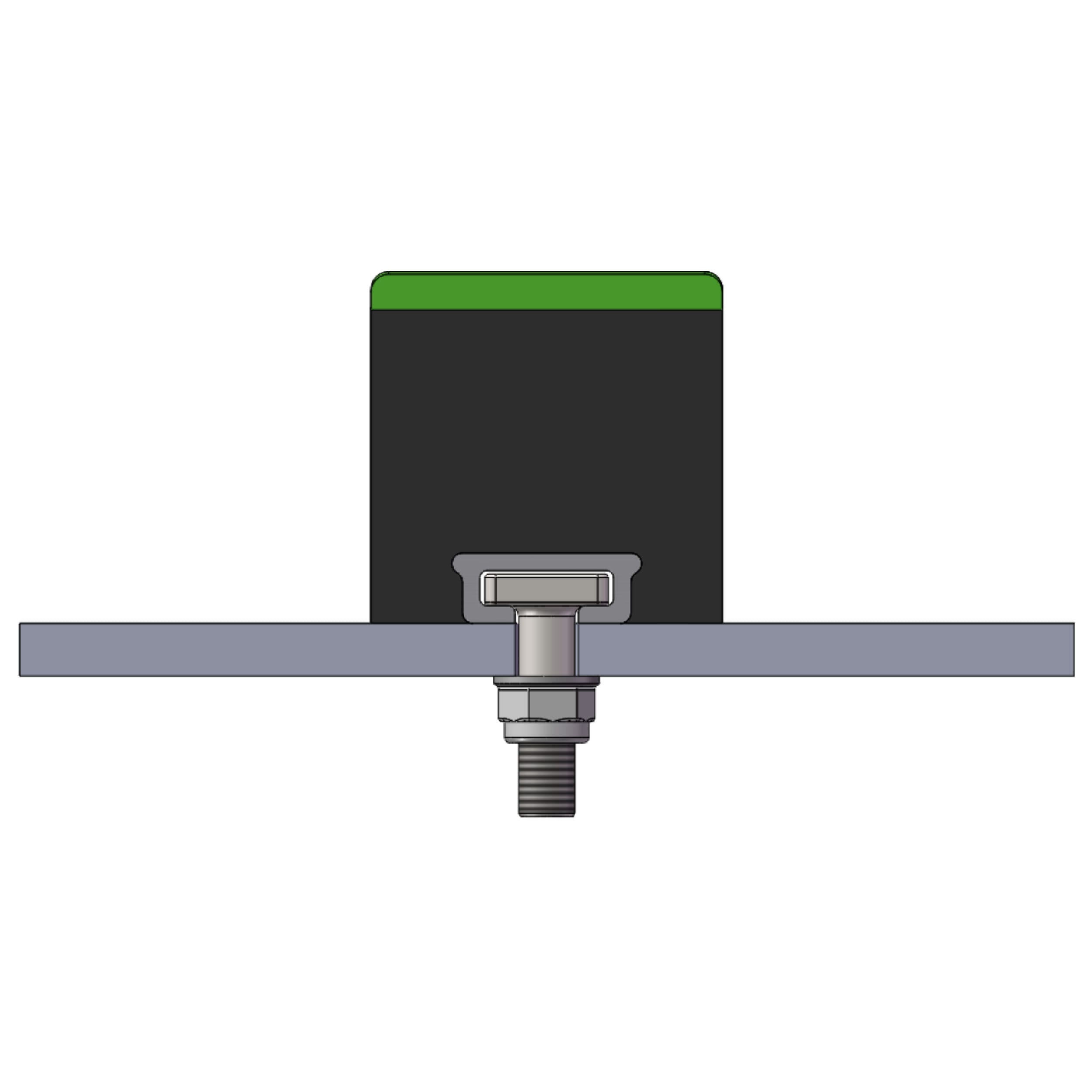

REMASLIDE ALOX

Wear resistant ceramic feeding system

REMASLIDE ALOX impact bars absorb the drop energy of the material impact. A proven REMA TIP TOP special rubber substrate is combined with a hard and very smooth sliding surface made of ceramic. The wear-resistant ceramic ensures a very long service life. By fully supporting the conveyor belt across the feed points and transfer stations, damage of the belt is avoided.

INTERNATIONAL

INTERNATIONAL