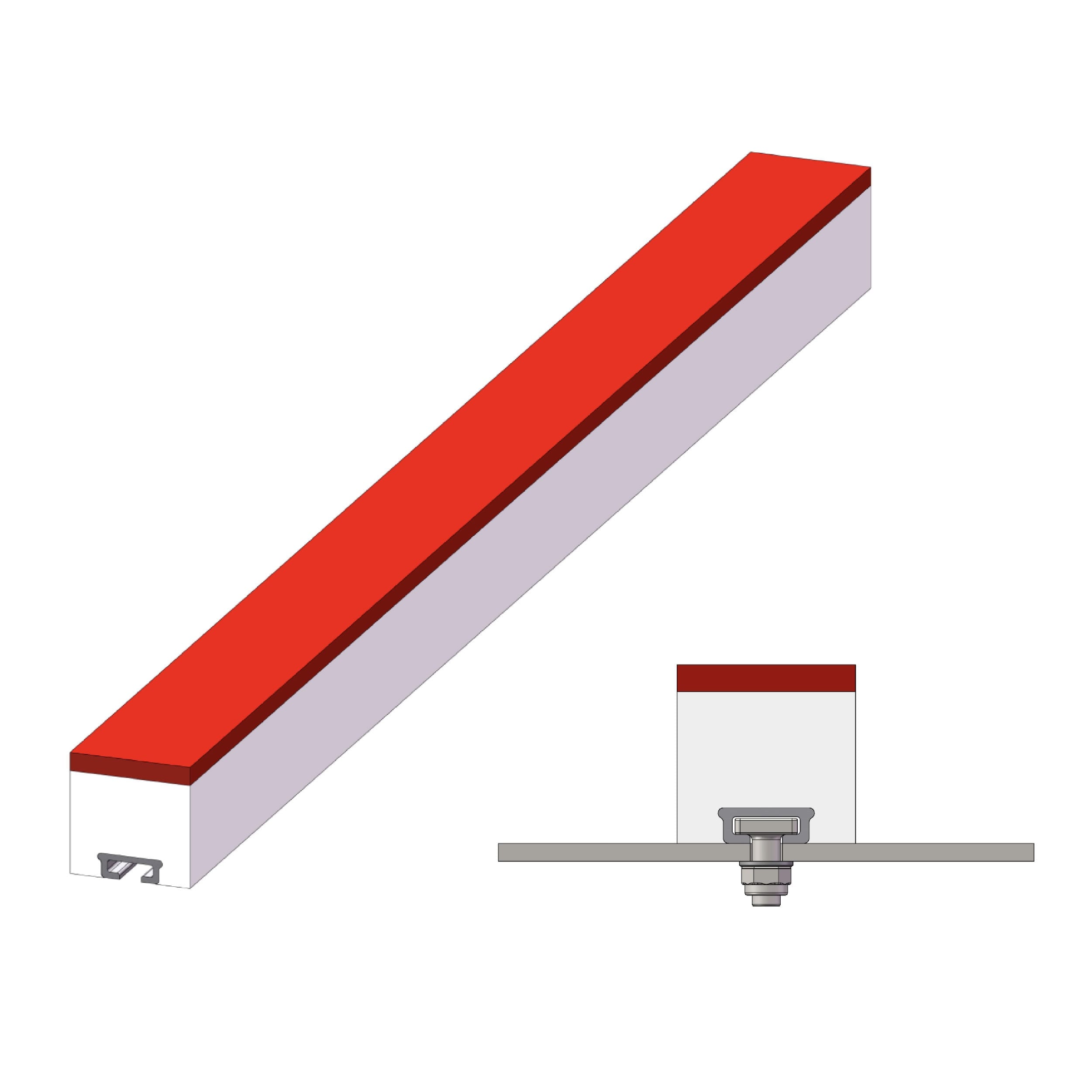

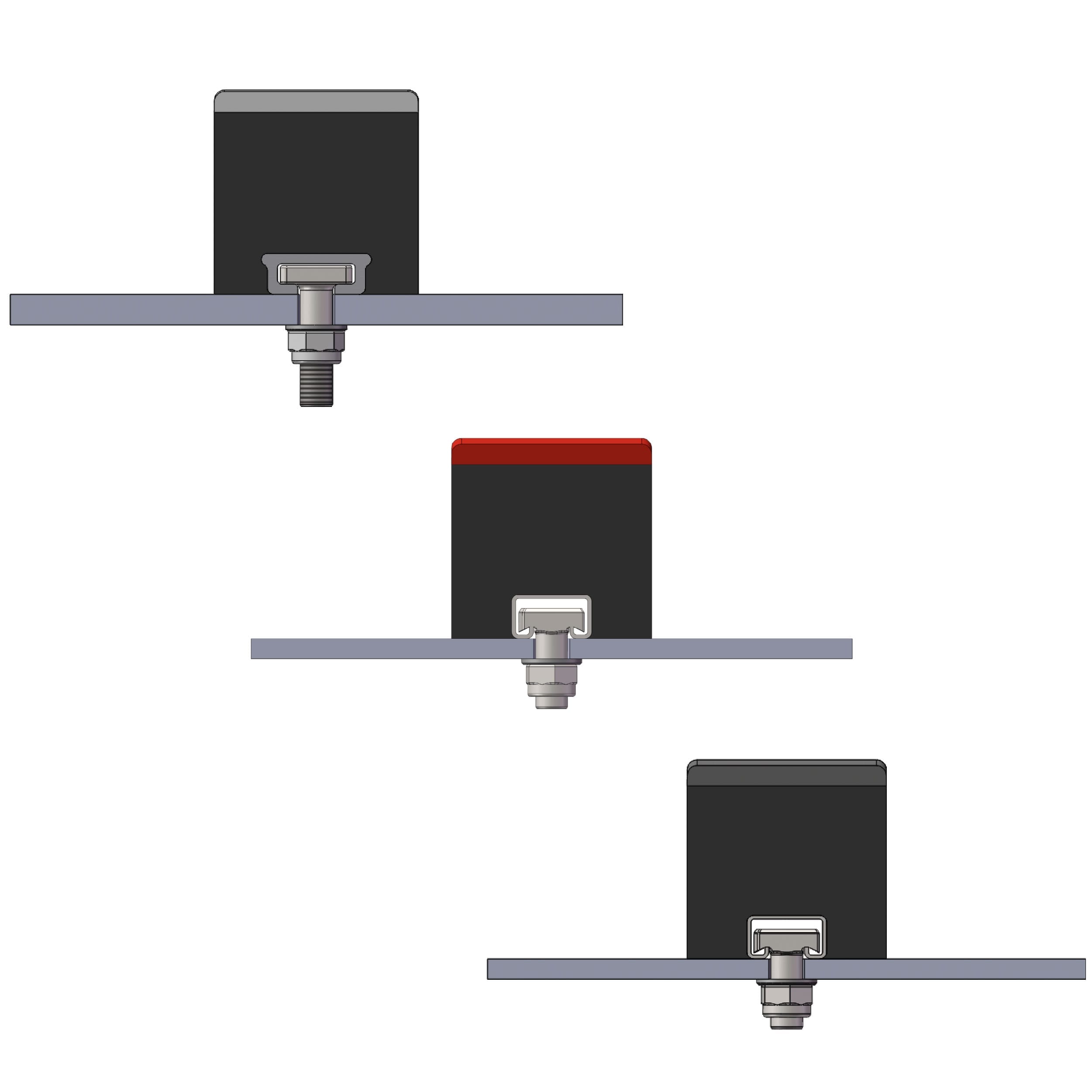

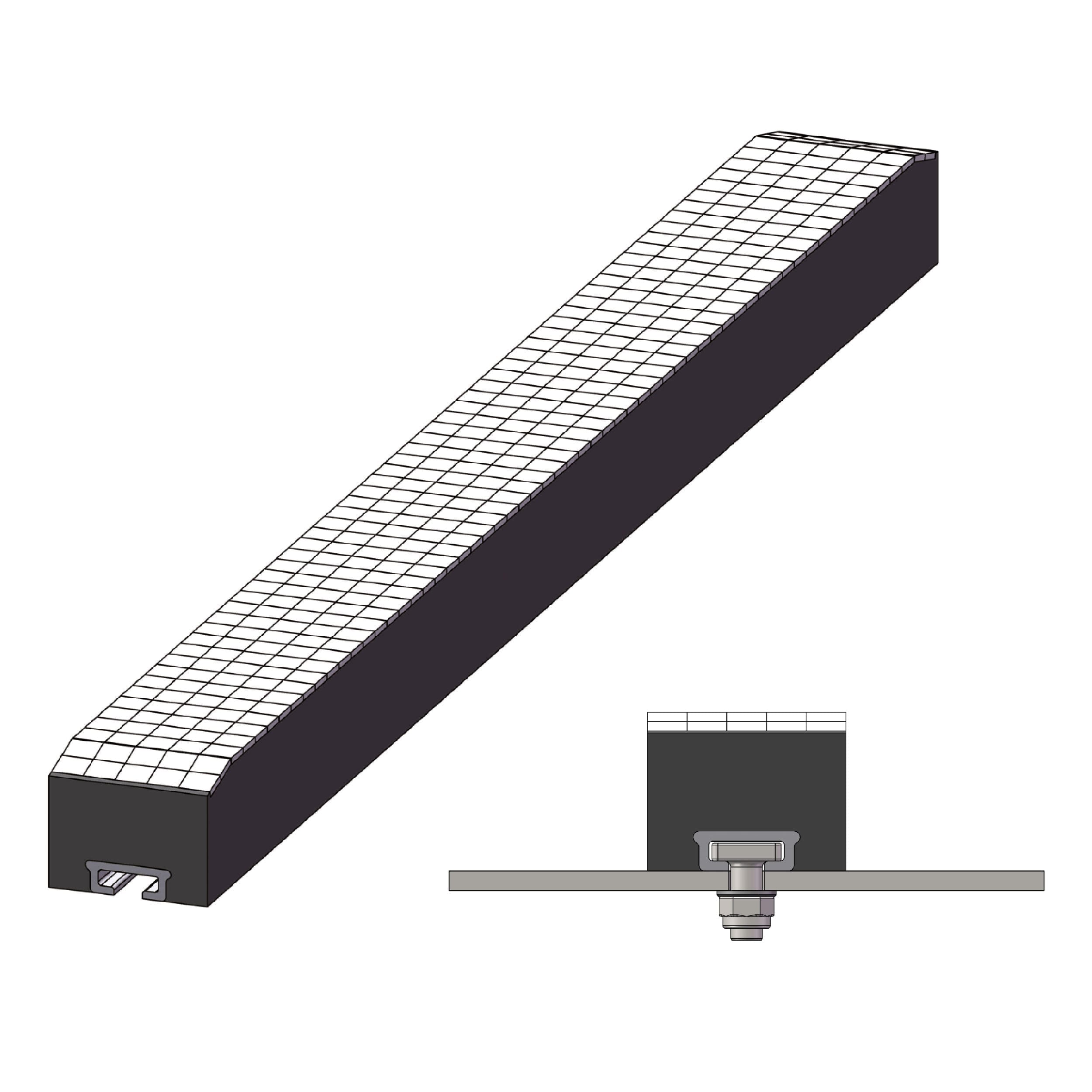

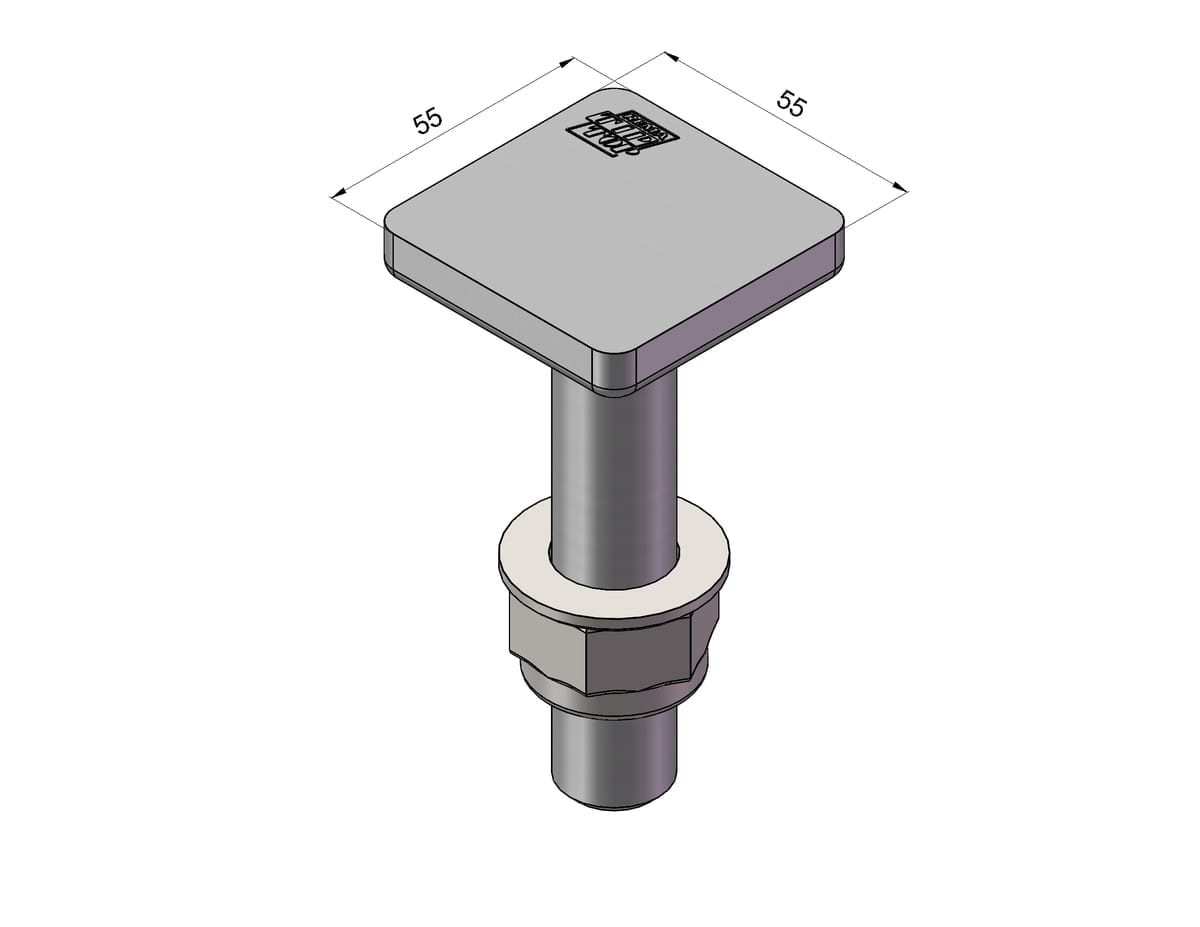

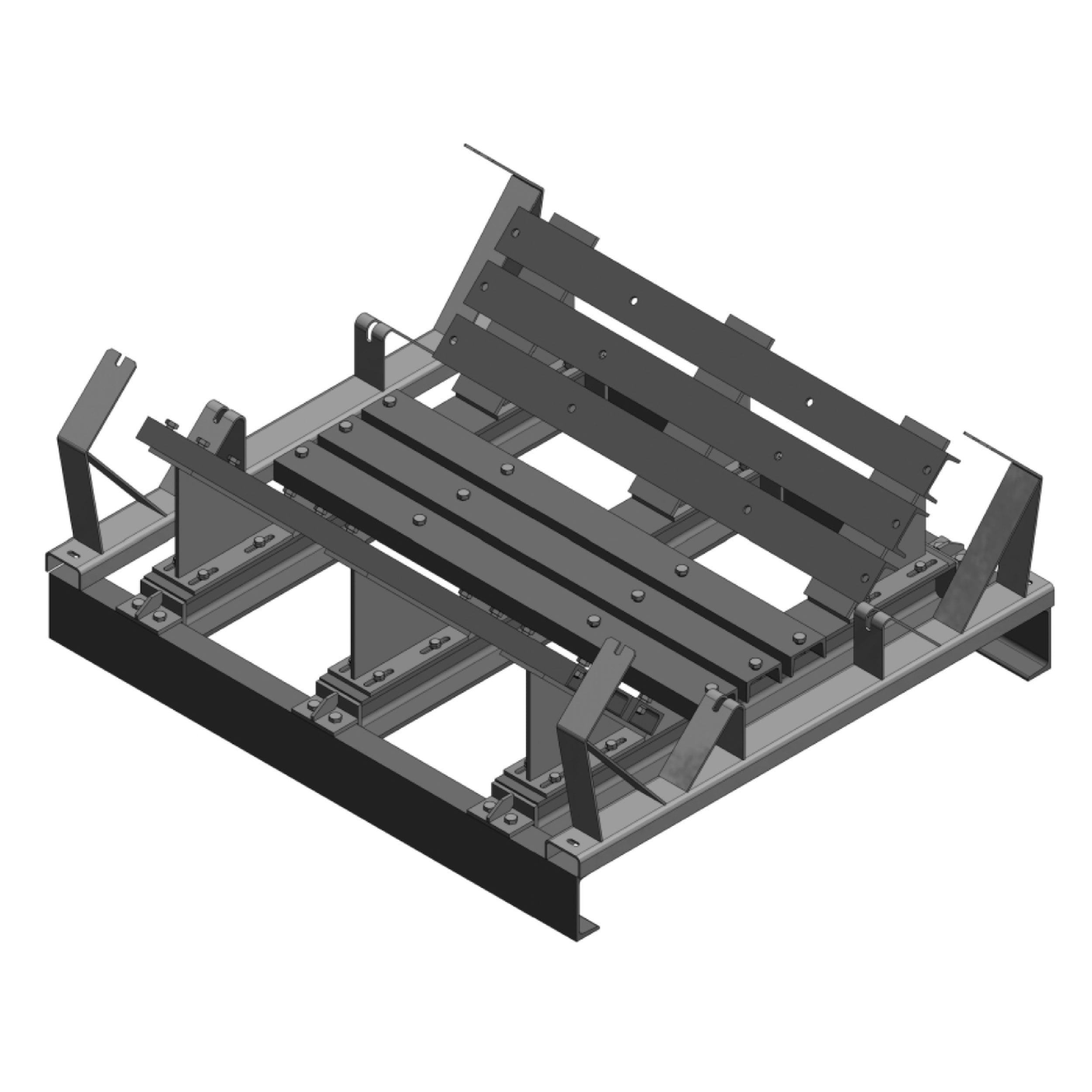

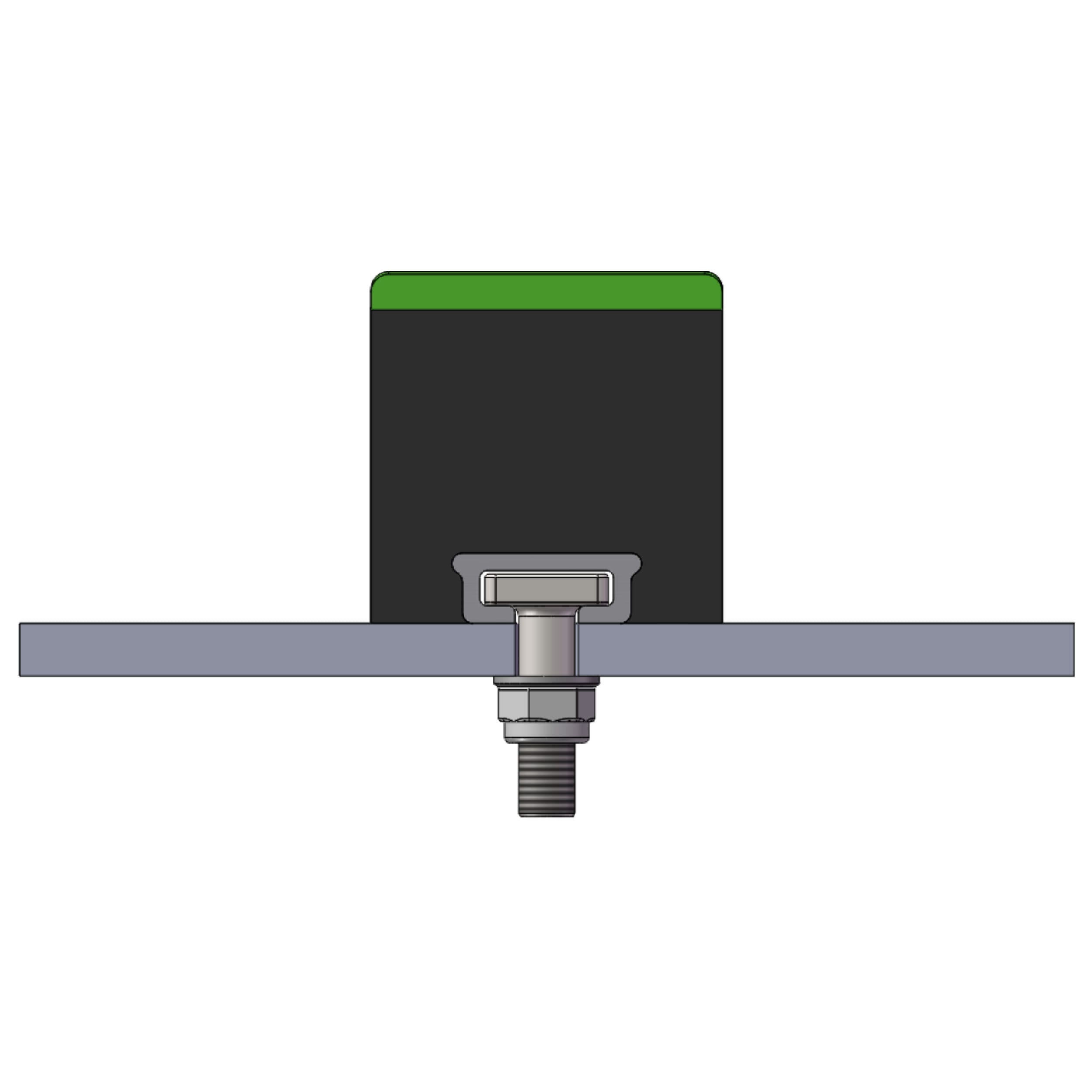

REMASLIDE PUR Impact Bars

Wear resistant polyurethane feeding system

REMASLIDE PUR impact bars absorb the drop energy of the impacting material at very high drop heights. The elastic PUR base and the sliding surface made of polyurethane absorb the impact energy. Through full support of the whole surface of the conveyor belt at the feed points and transfer stations, damage of the belt is avoided. It also ensures better plant availability.

INTERNATIONAL

INTERNATIONAL