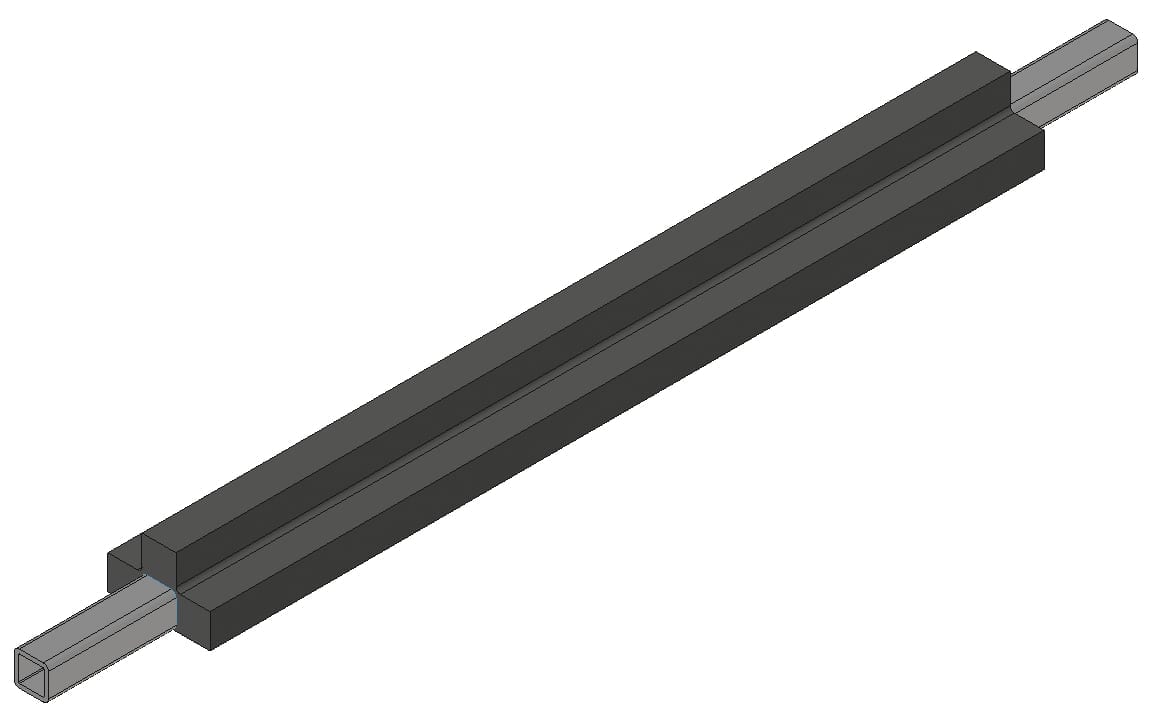

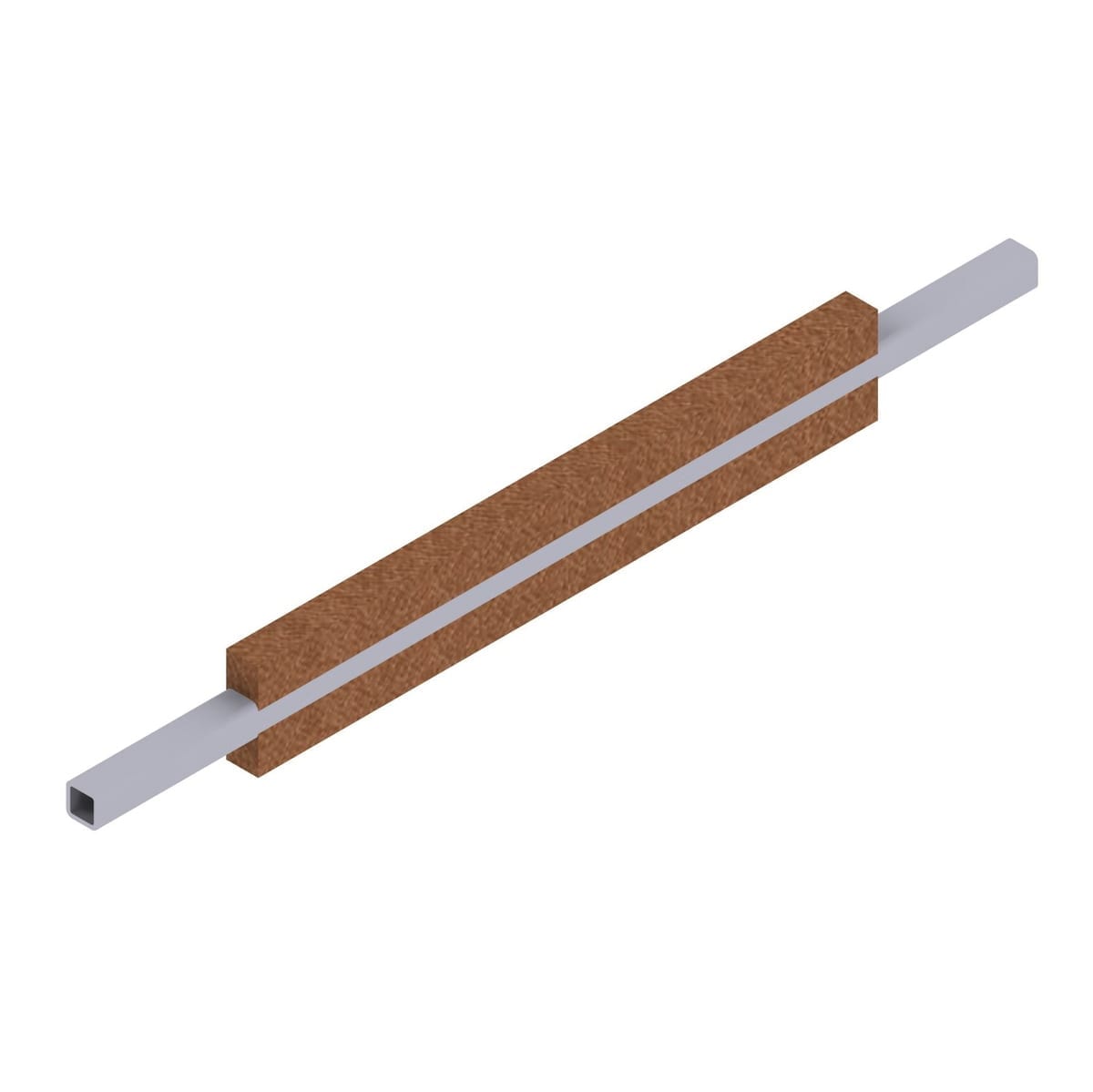

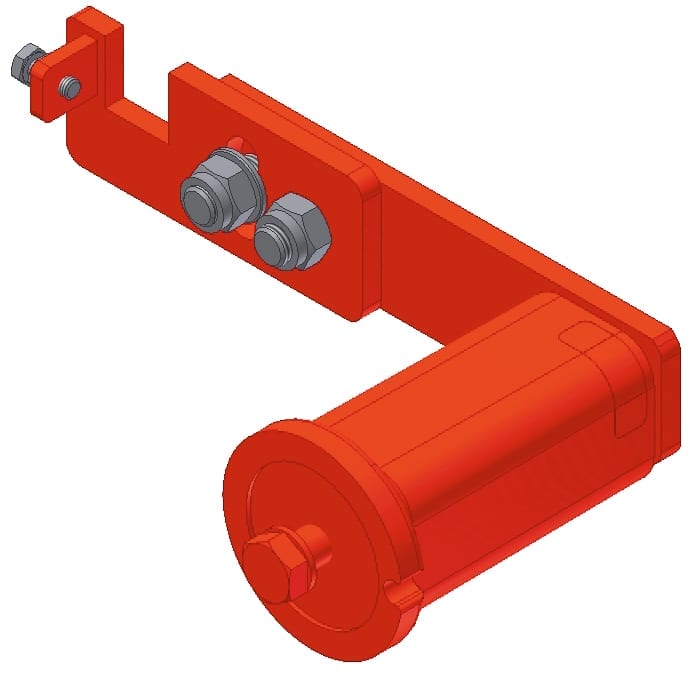

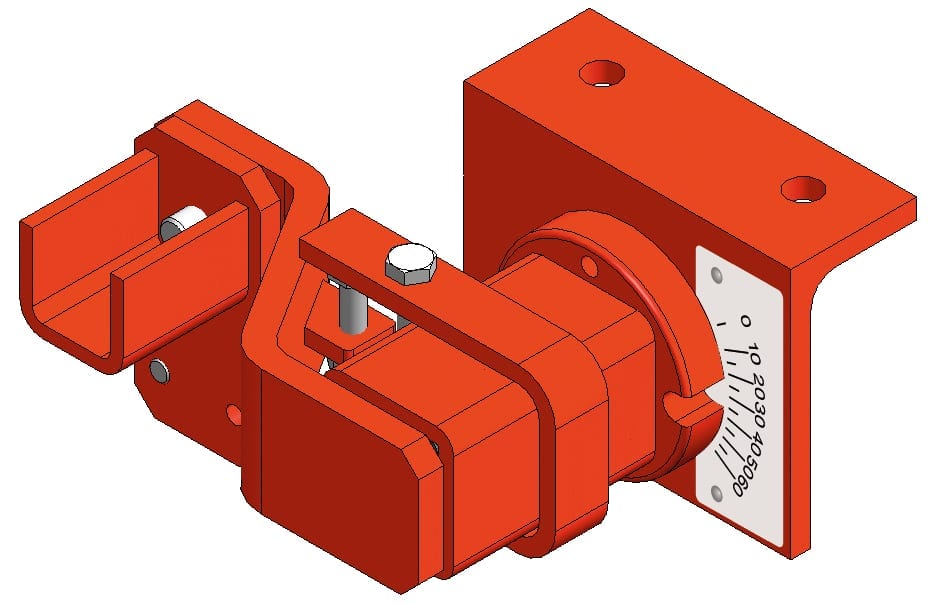

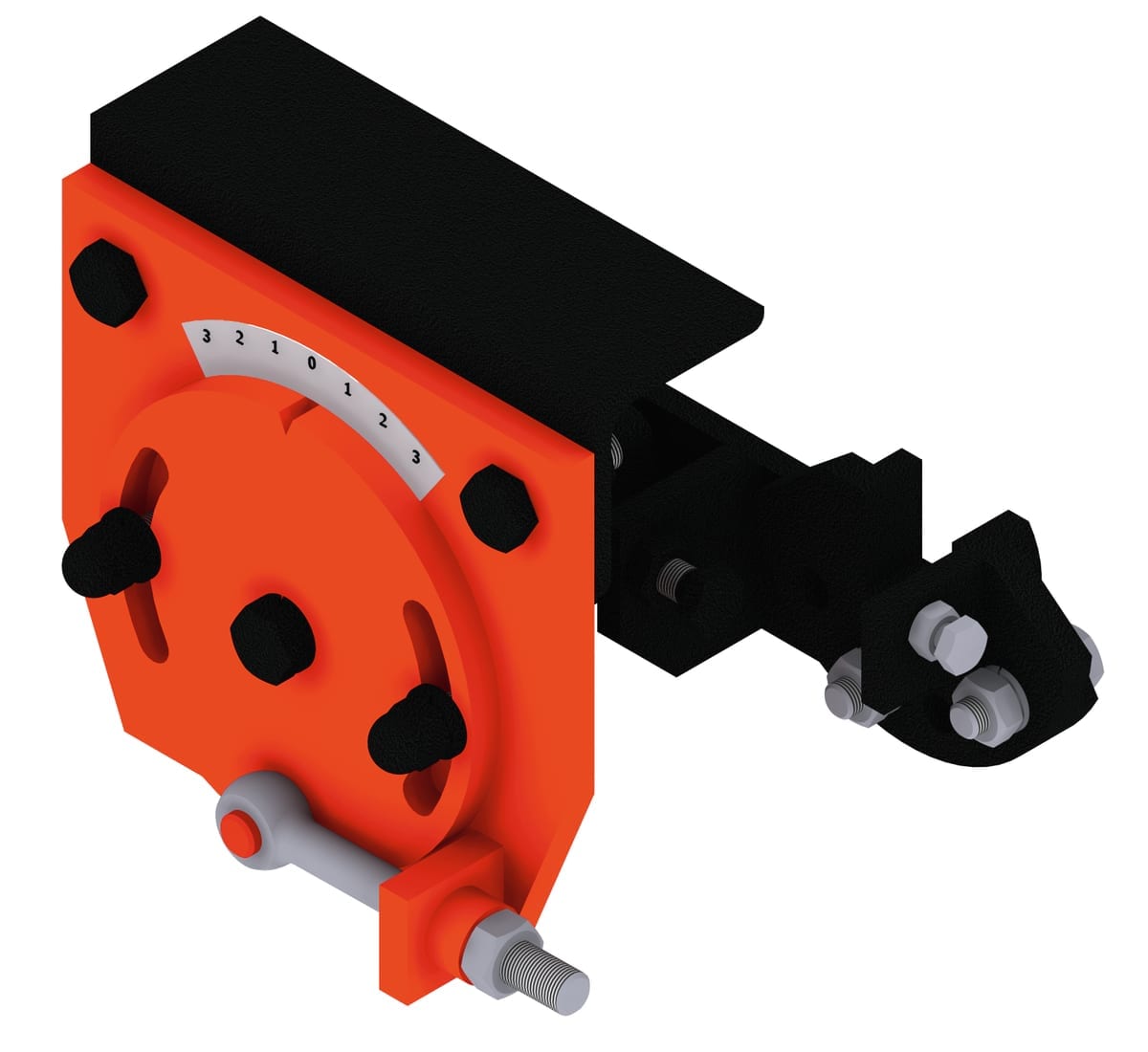

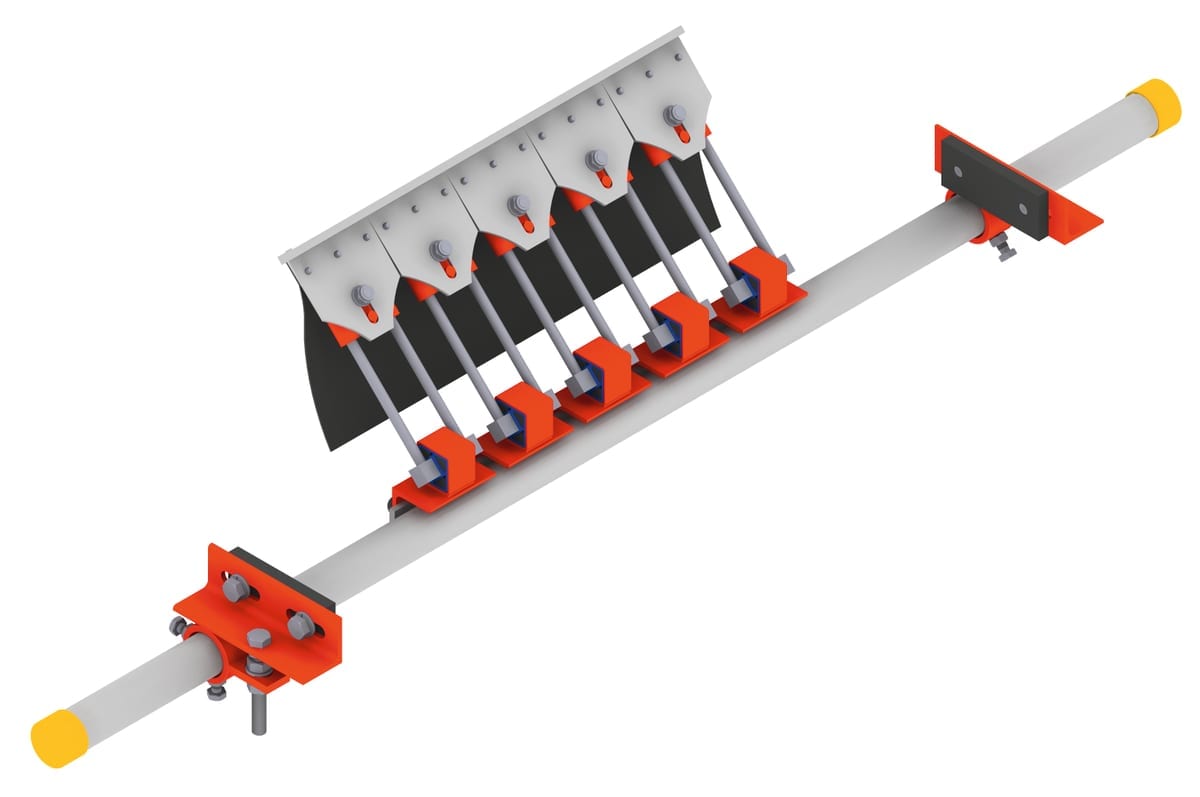

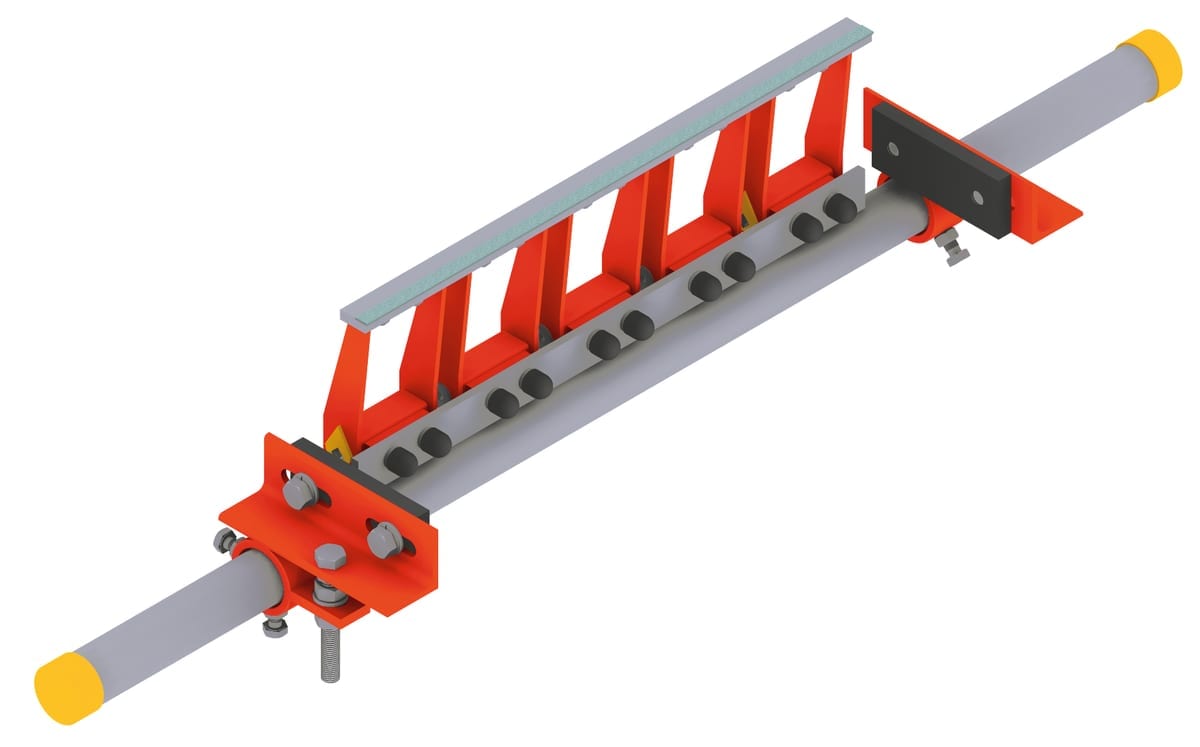

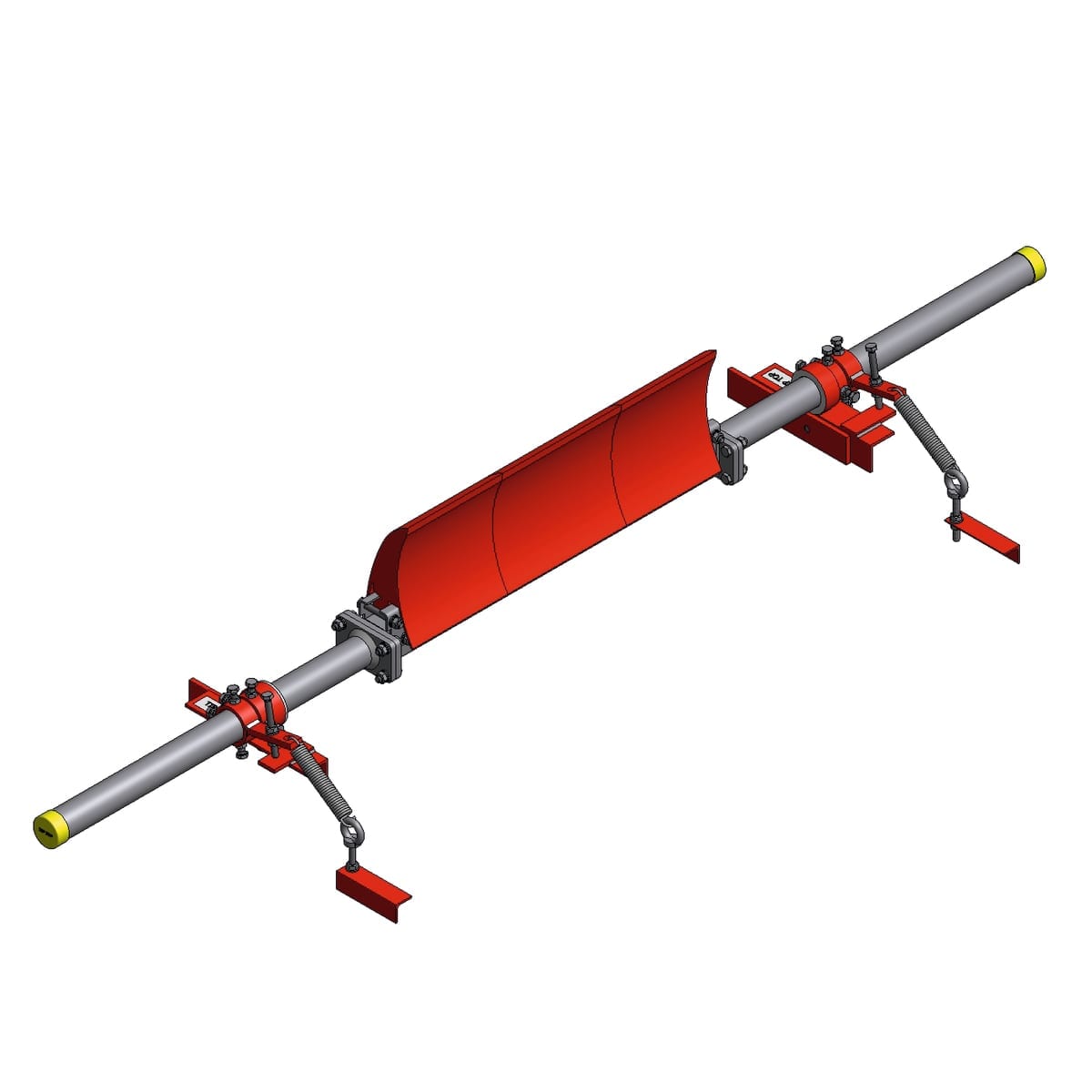

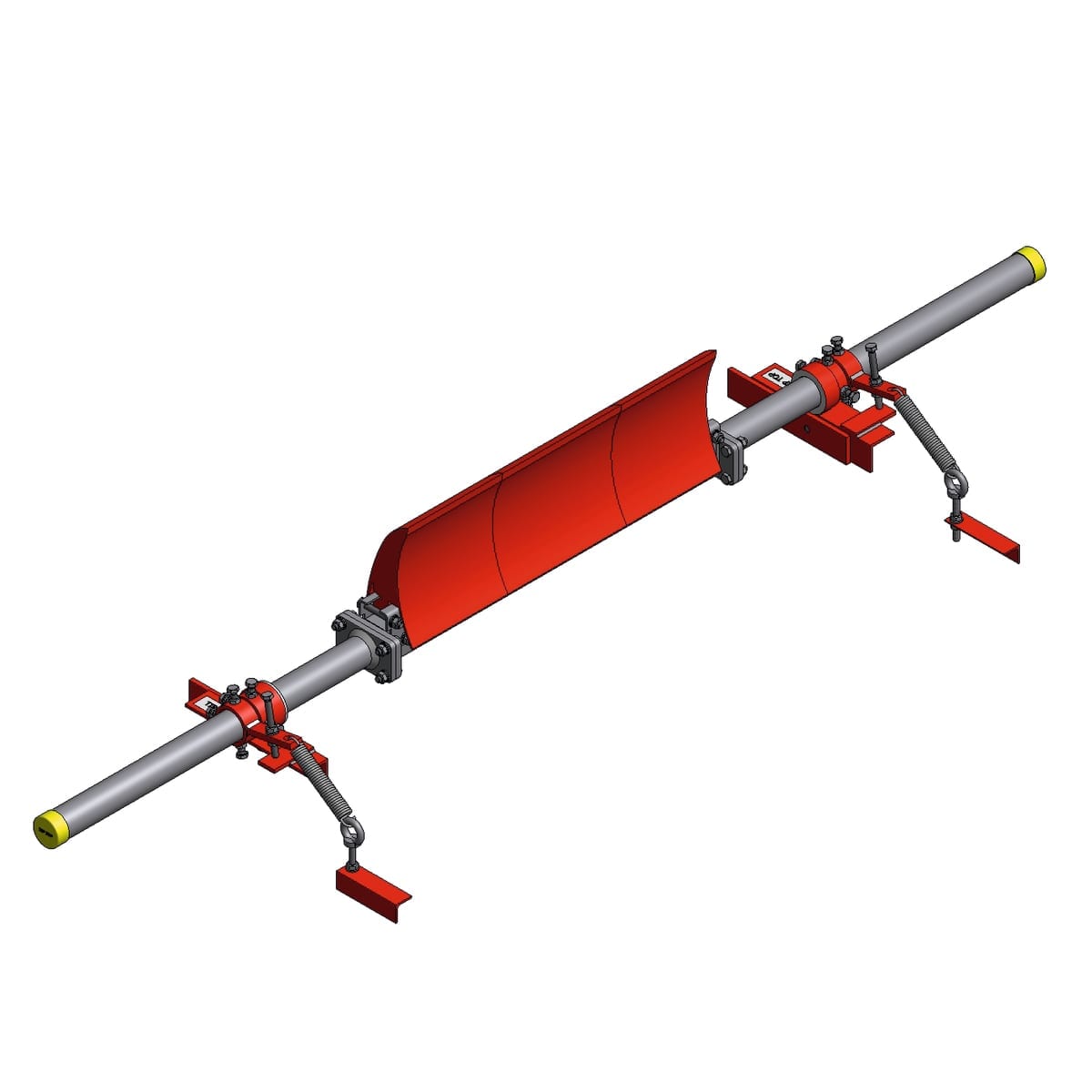

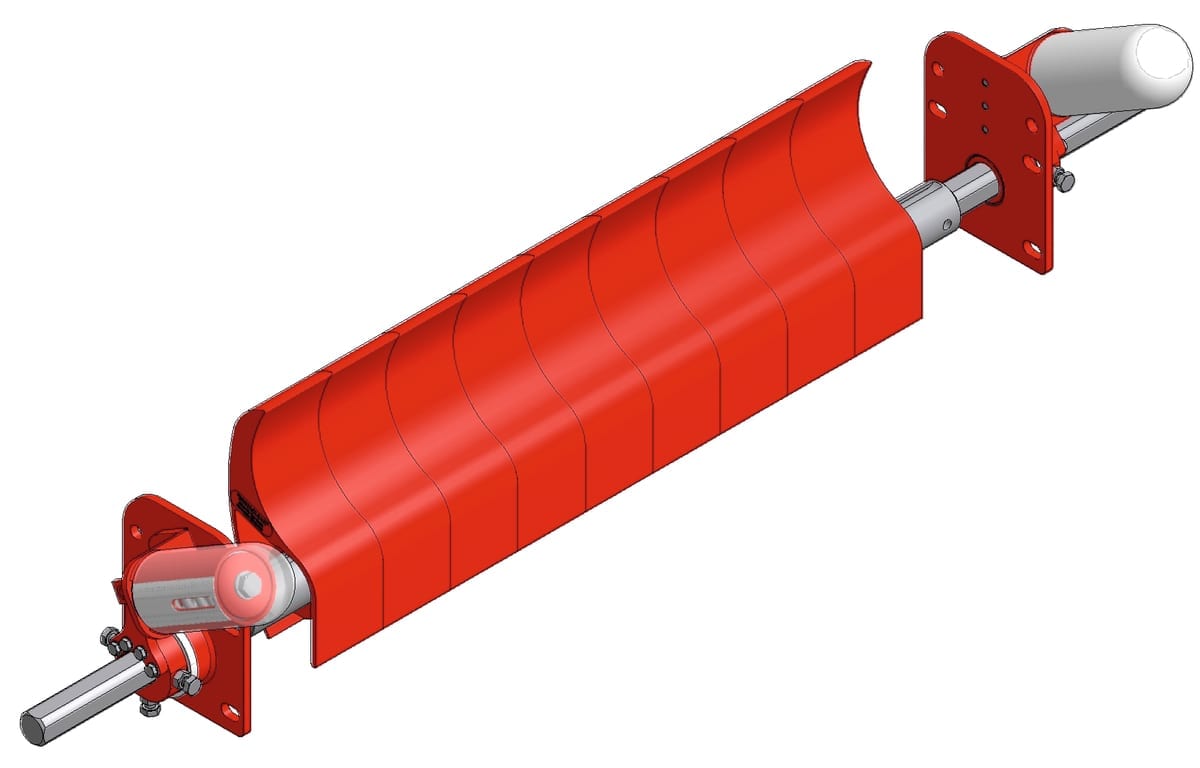

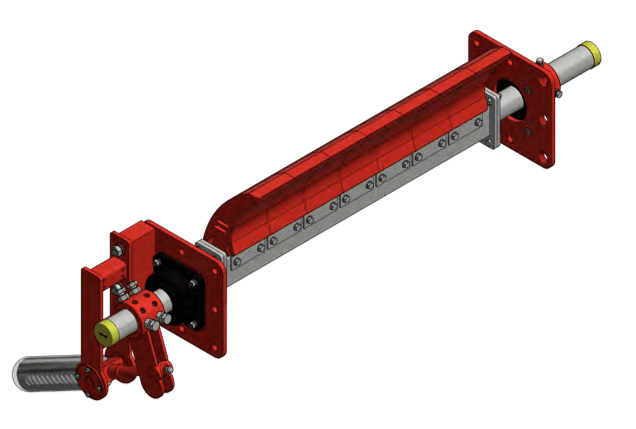

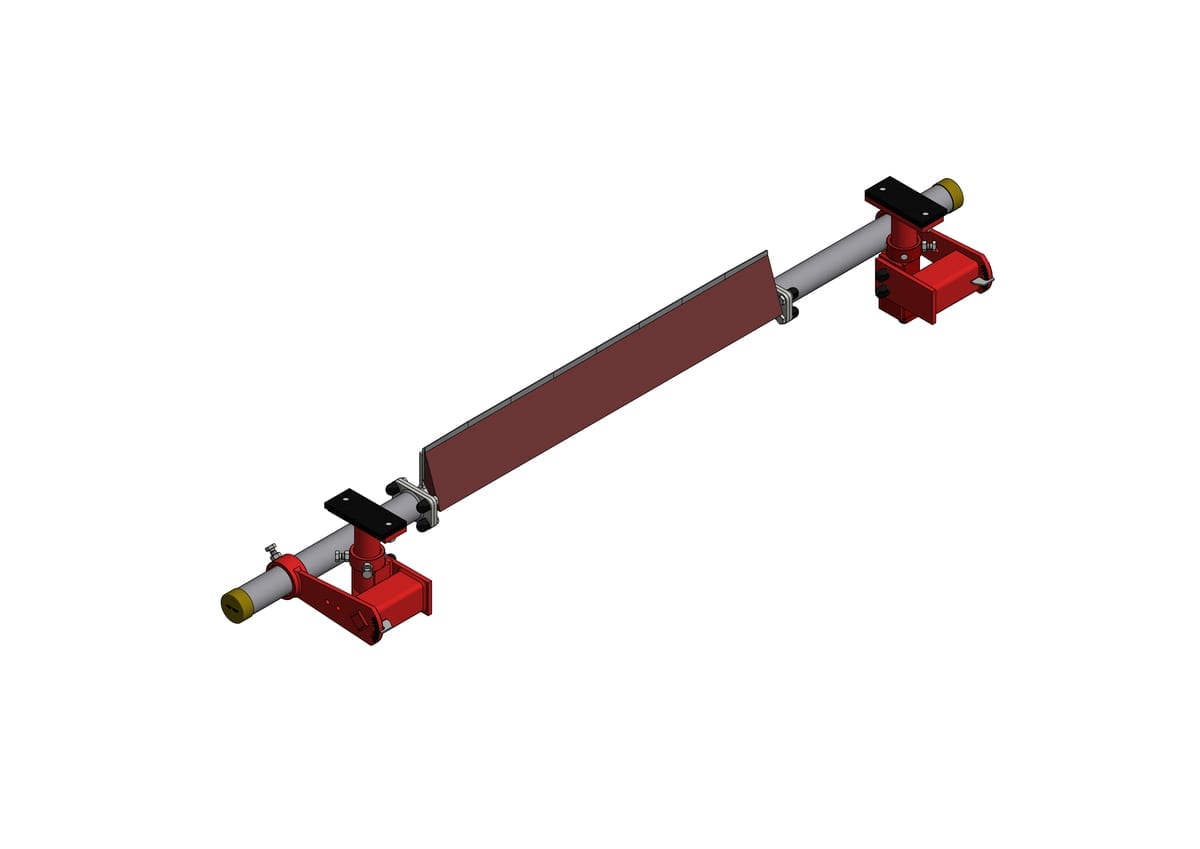

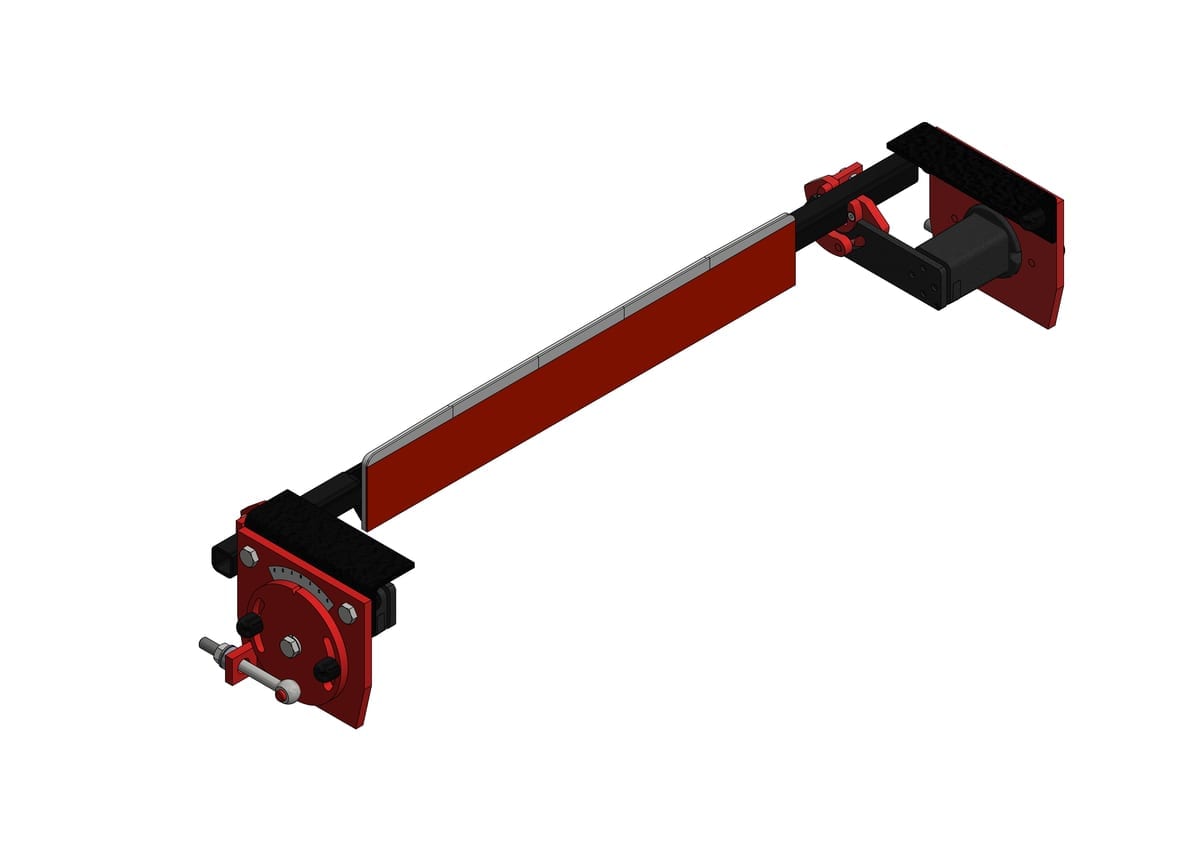

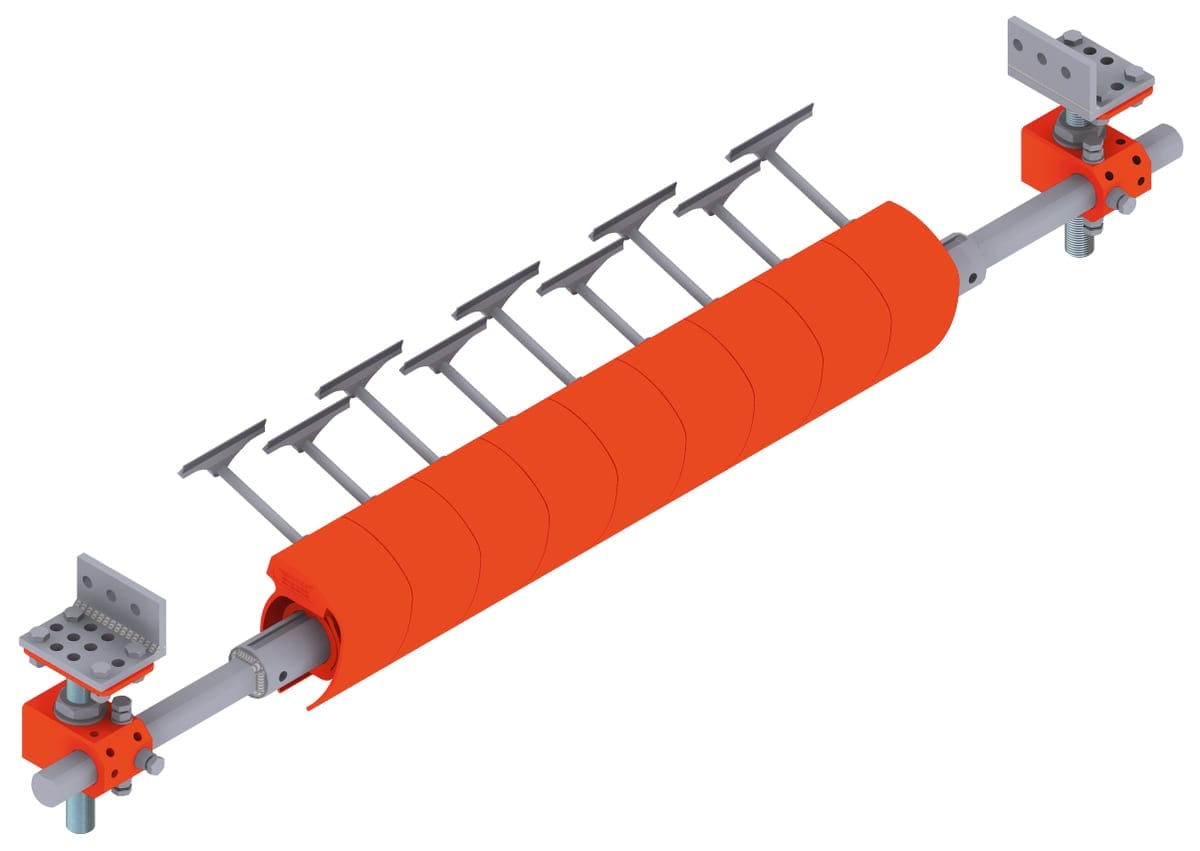

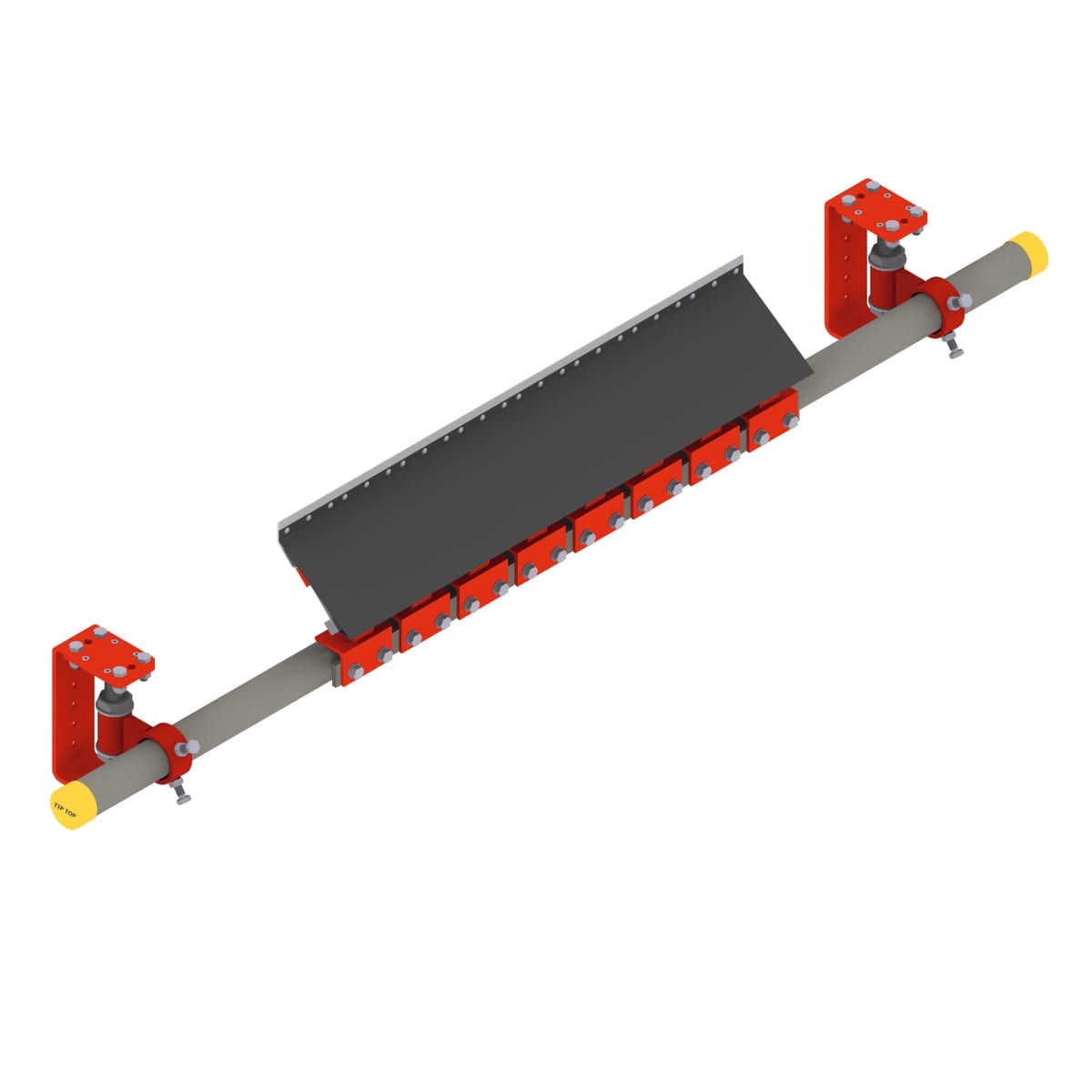

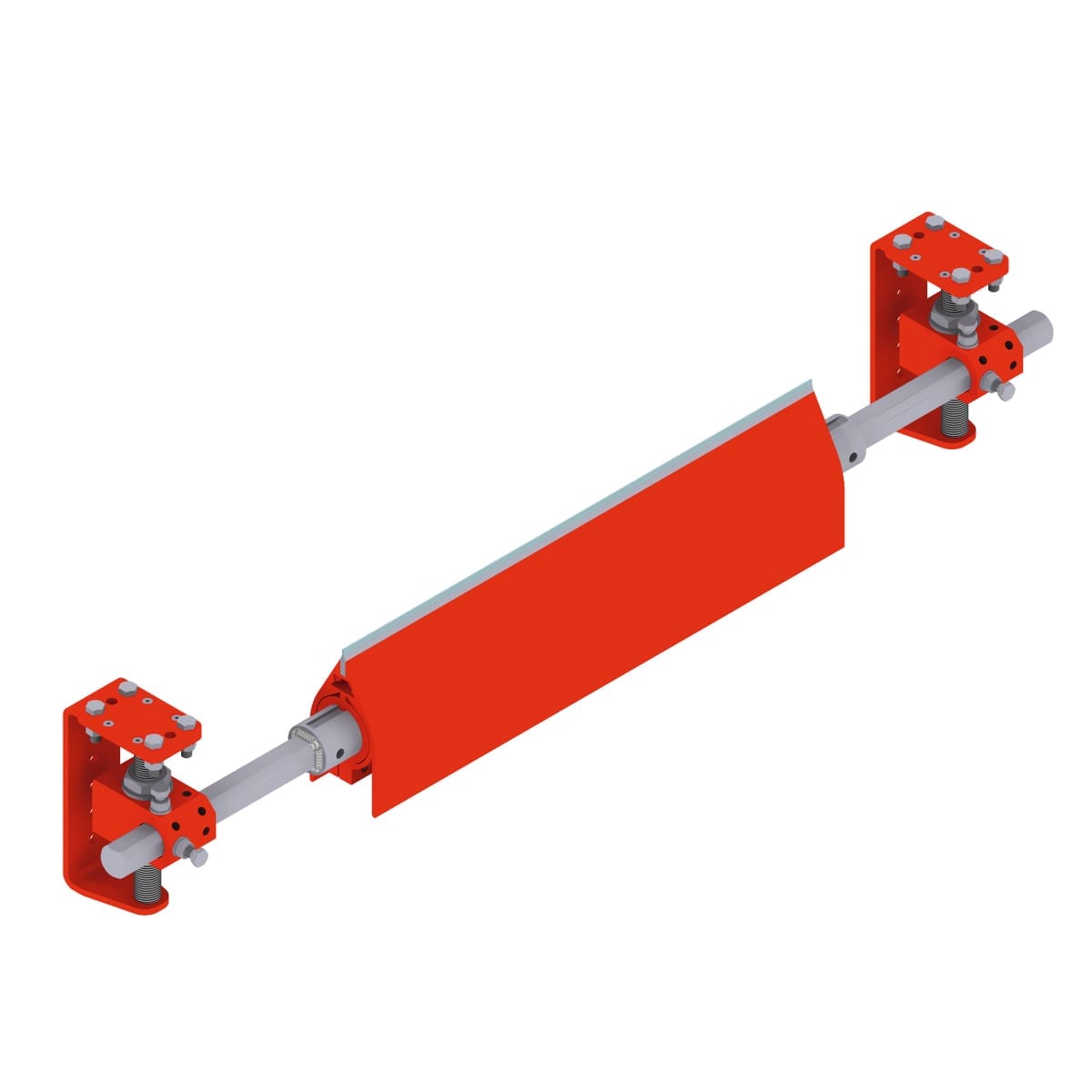

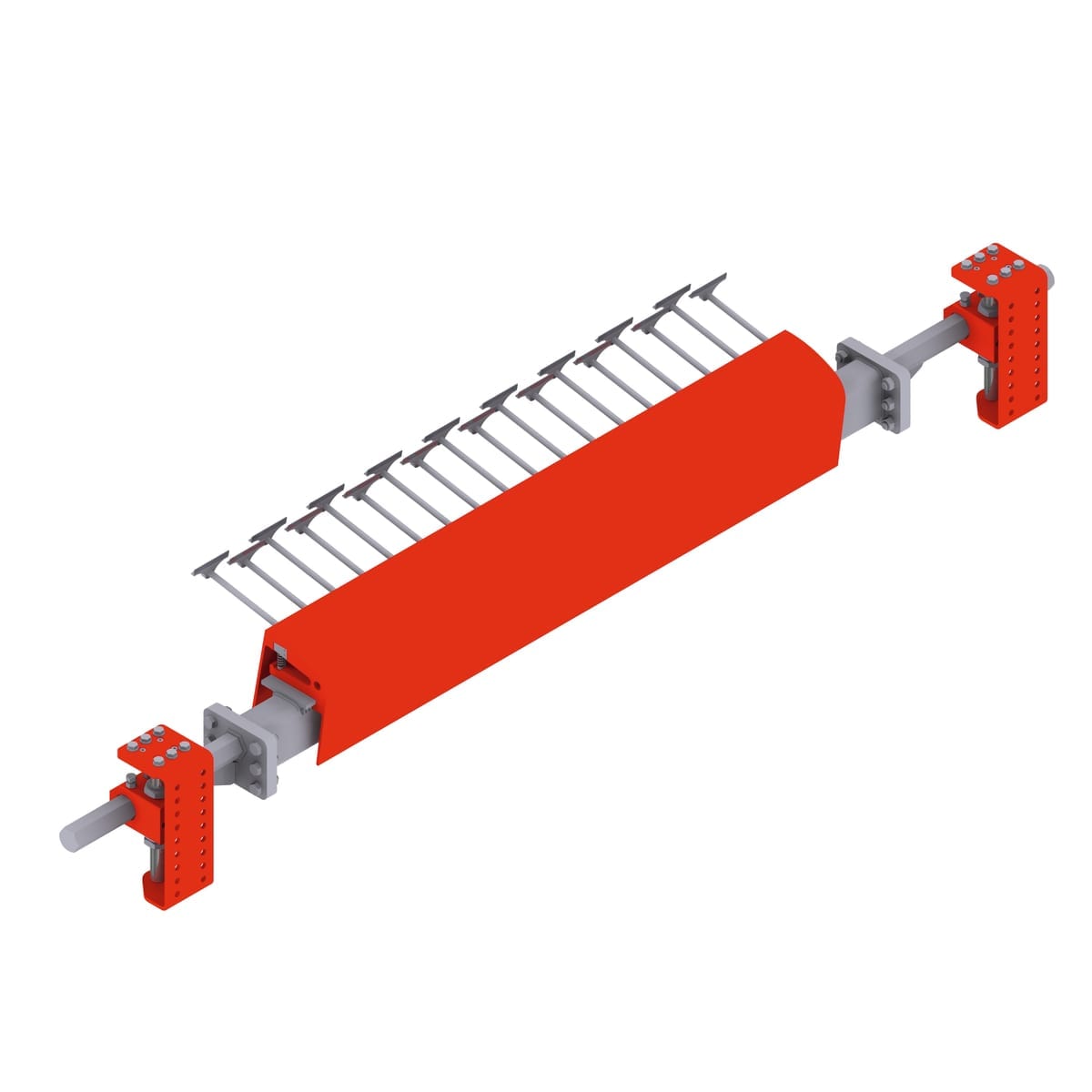

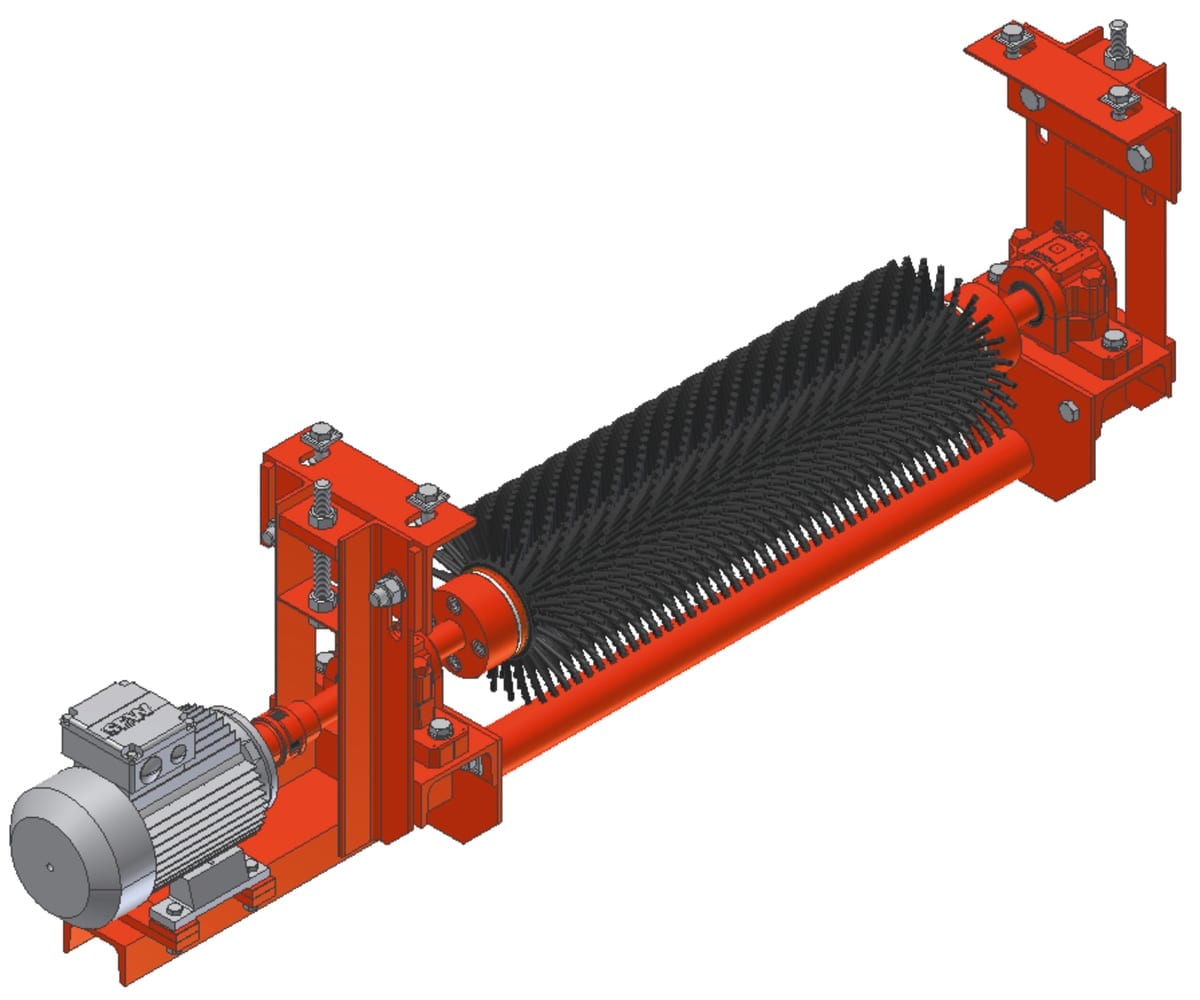

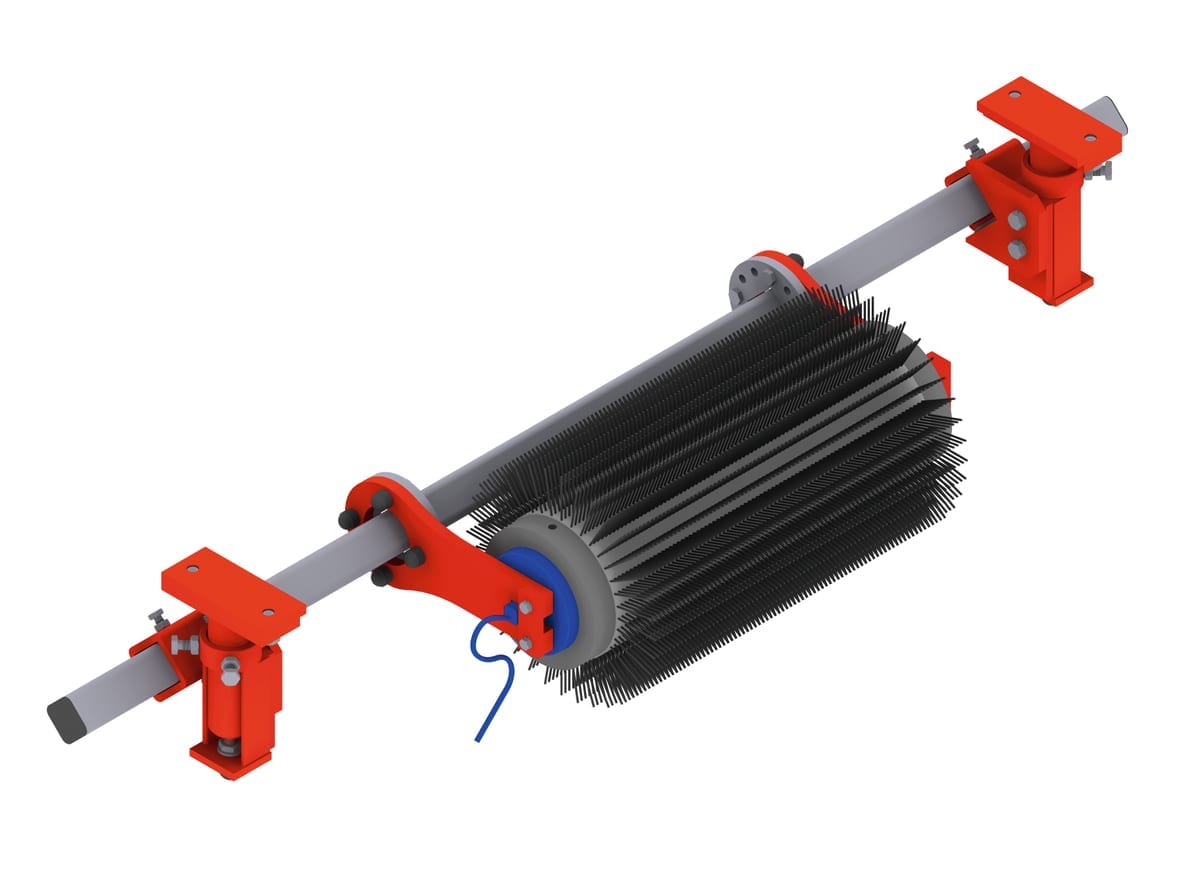

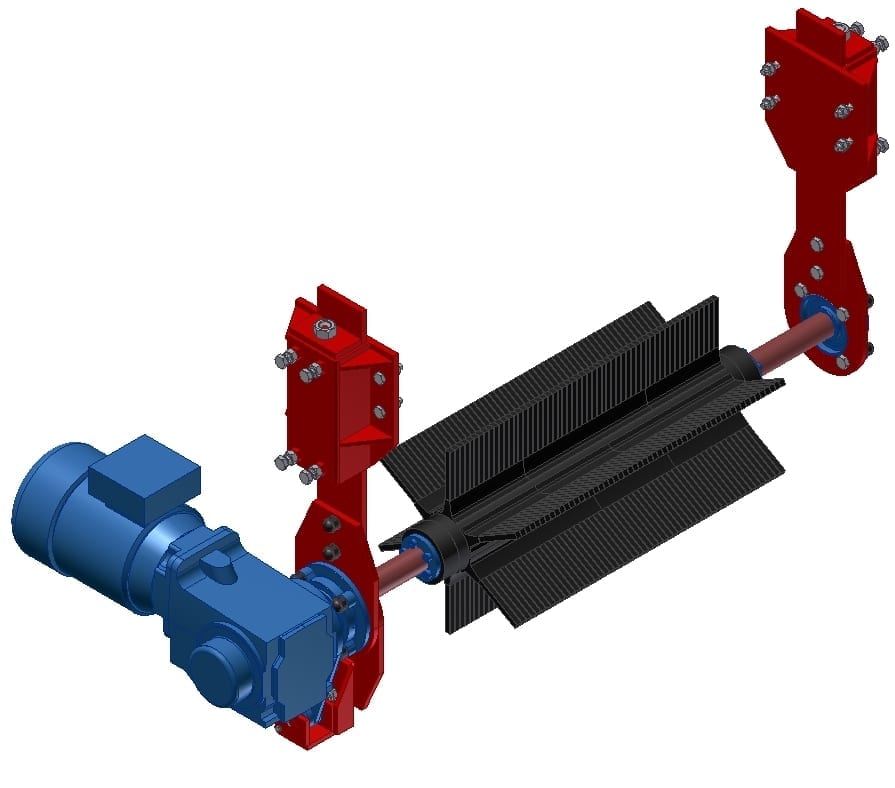

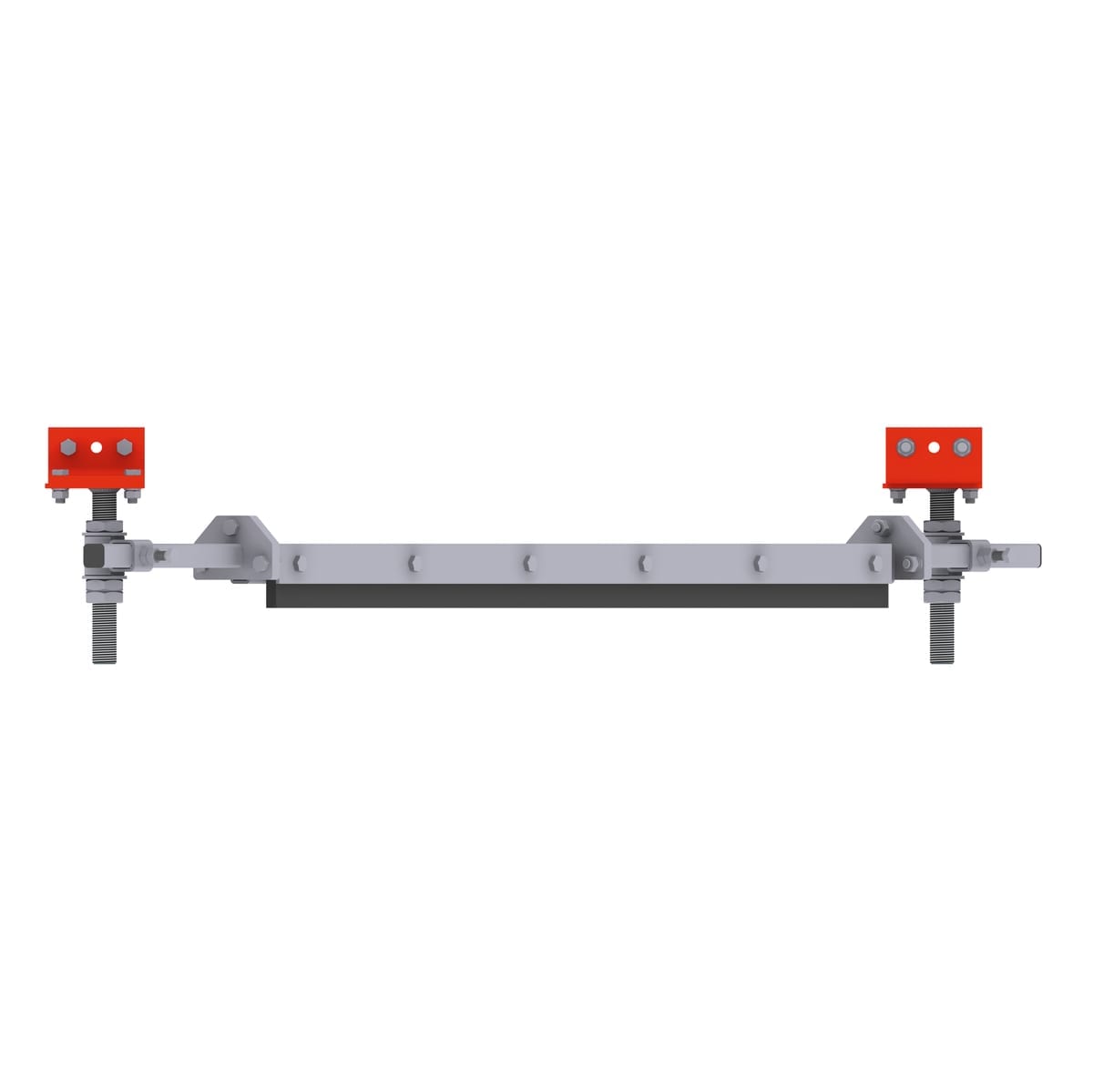

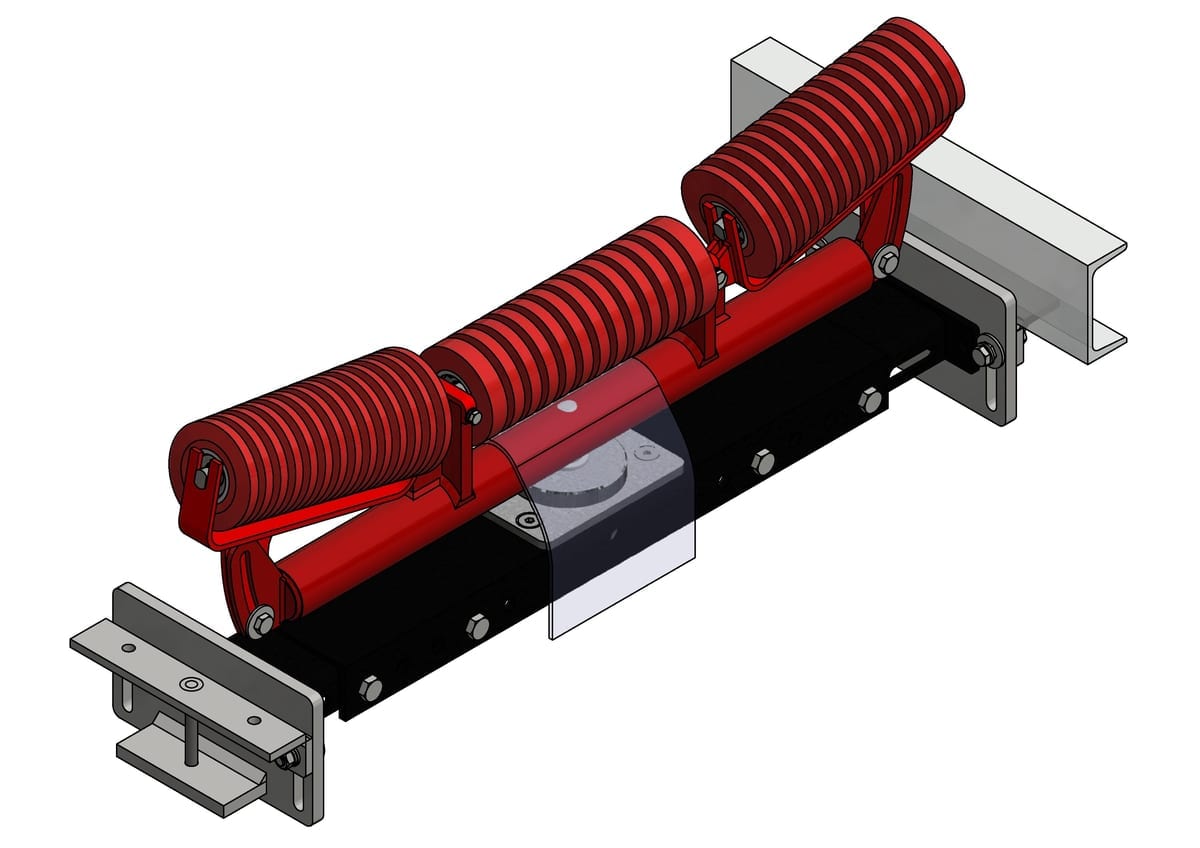

REMACLEAN Retractable Belt Cleaners

REMA TIP TOP retractable belt cleaning systems are ergonomically designed to reduce manual handling and allow for extremely quick scraper servicing. This leads to improved safety, increased conveyor availability and reduced clean up costs. Our retractable cleaning systems are made with safety, funcionality and quality in mind giving our customers value for money whilst tailoring solutions that are cost effective and safer for their workforce.

INTERNATIONAL

INTERNATIONAL