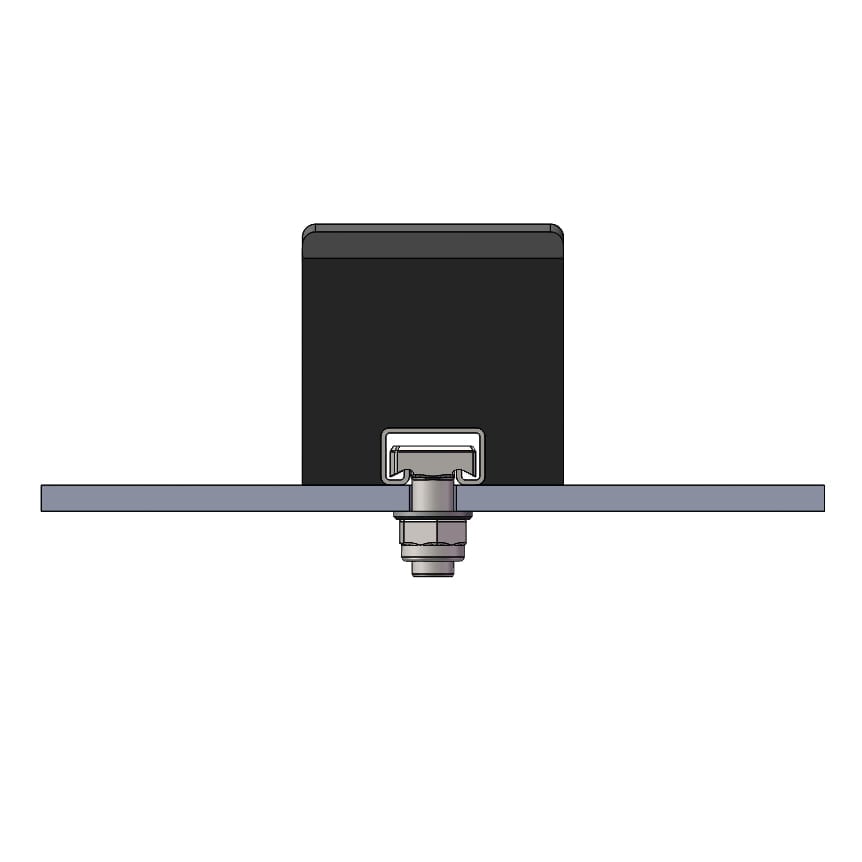

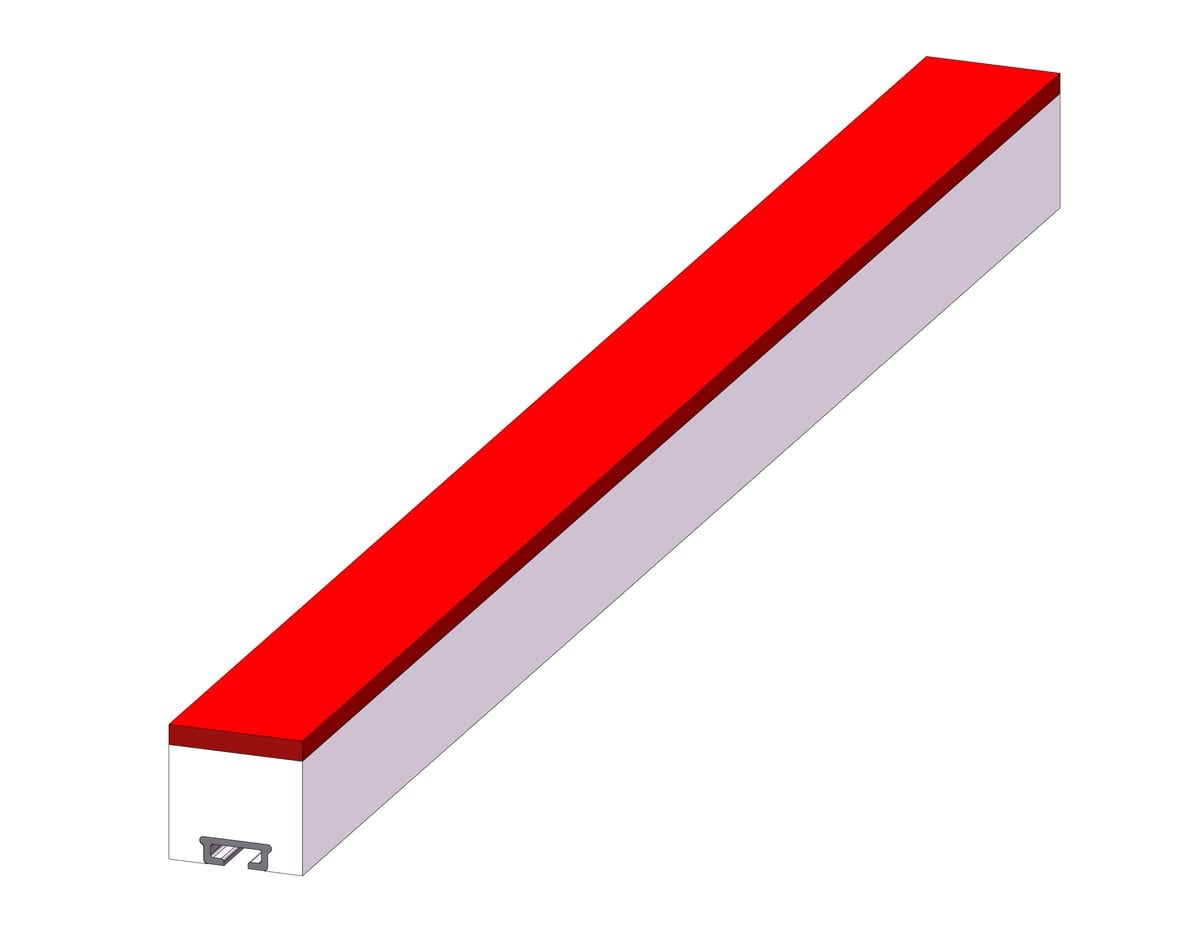

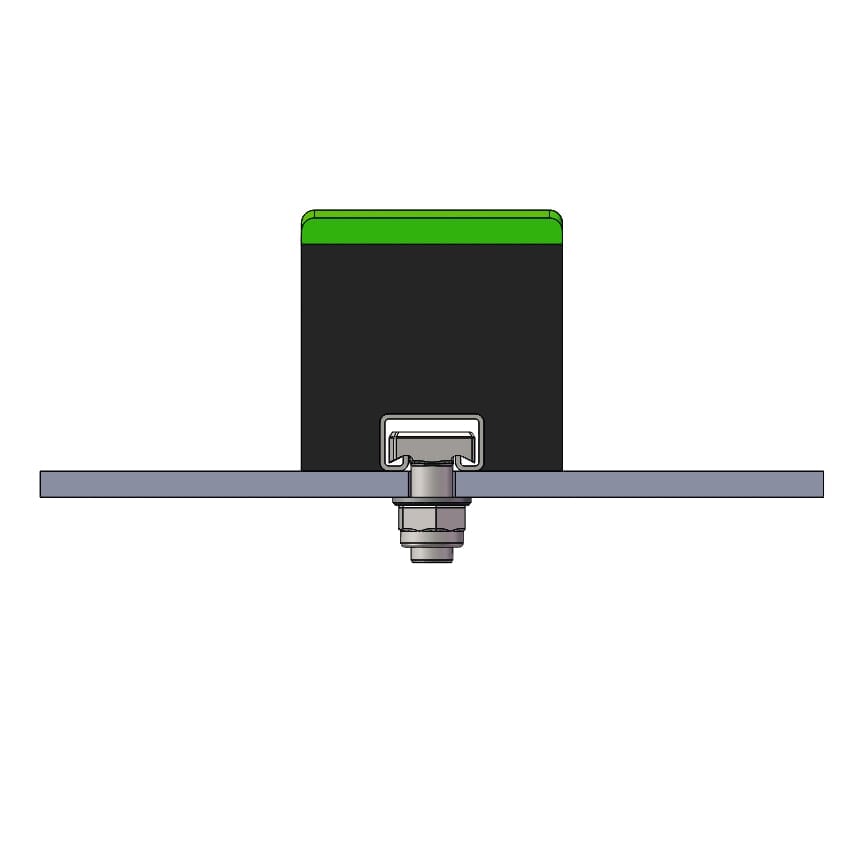

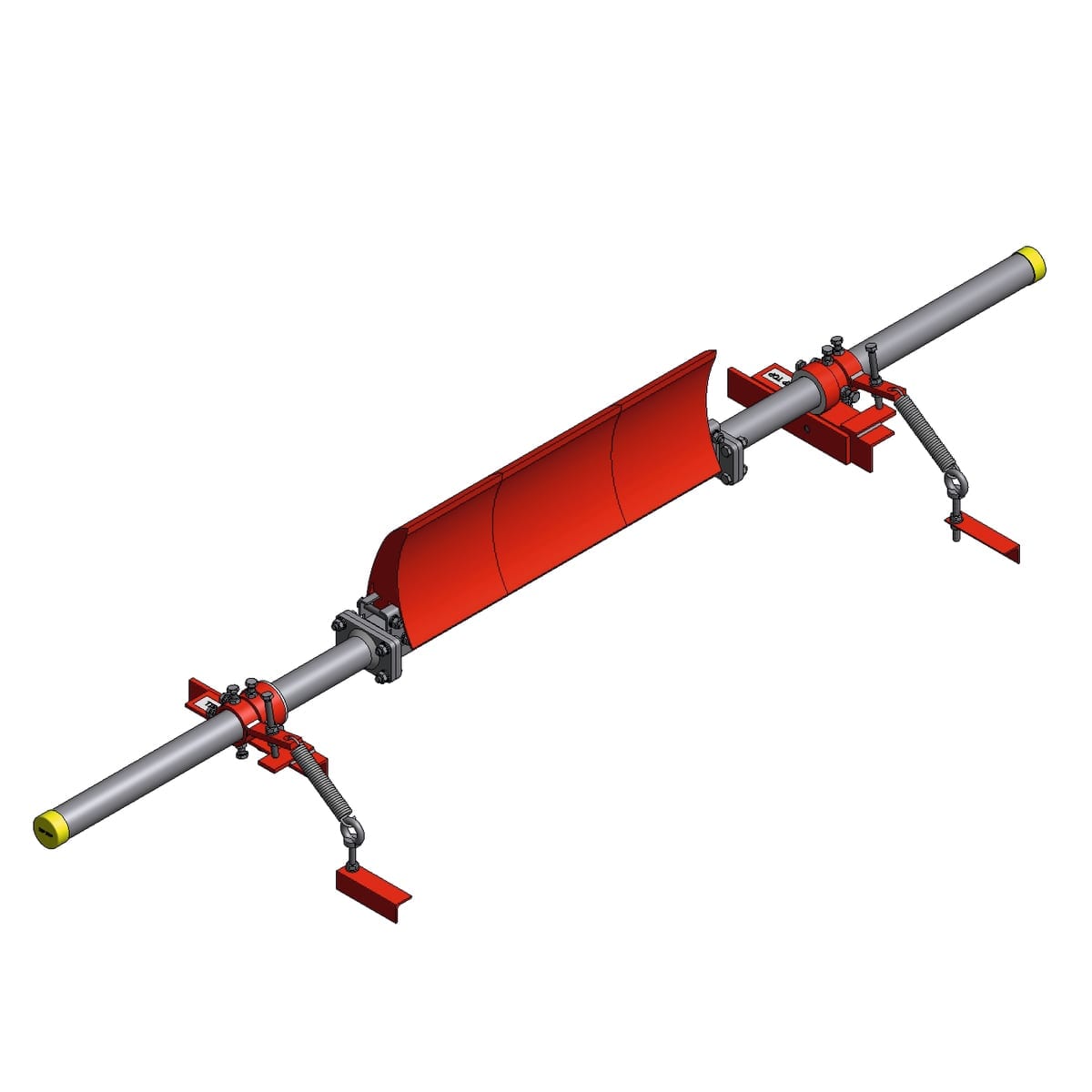

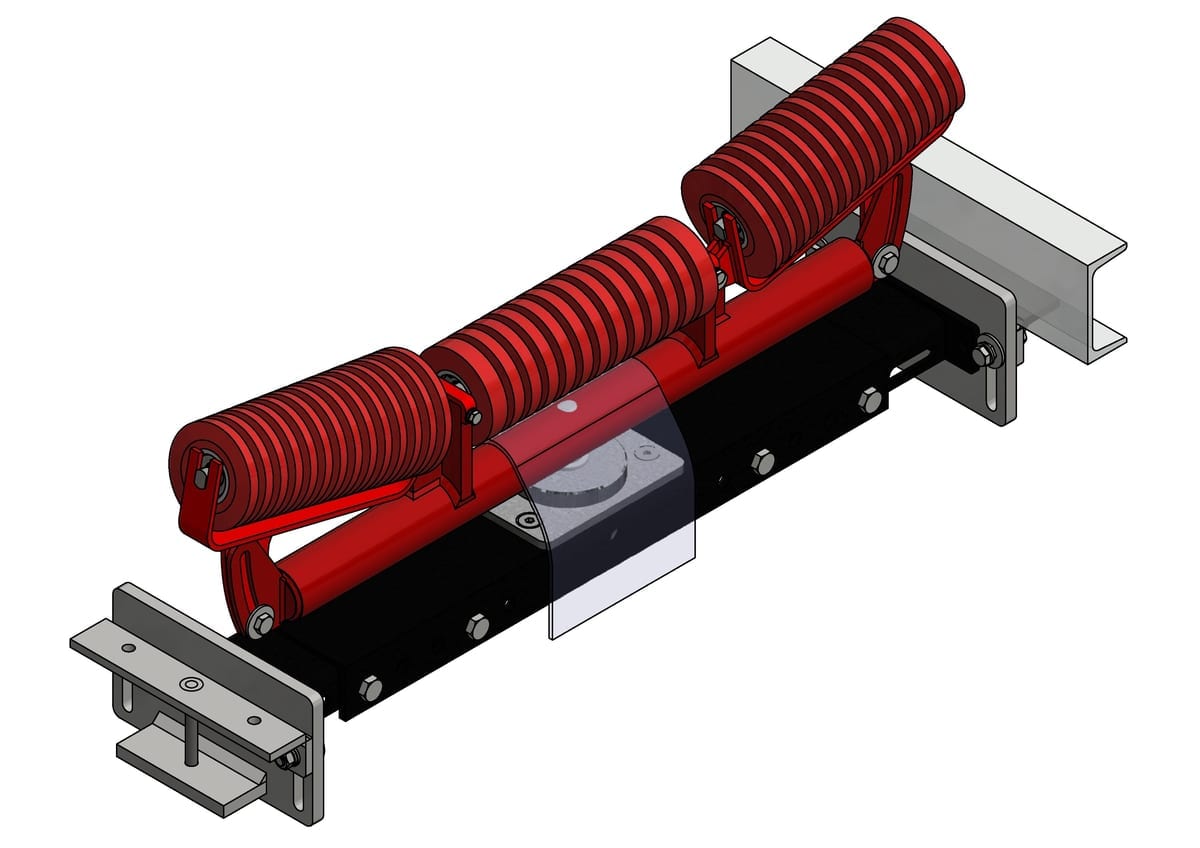

REMASLIDE impact bars

REMASLIDE impact bars absorb the drop energy of material impact through their proven REMA TIP TOP special rubber substrate. By fully supporting the conveyor belt across the feed points and transfer stations, damage of the belt will be avoided.

INTERNATIONAL

INTERNATIONAL