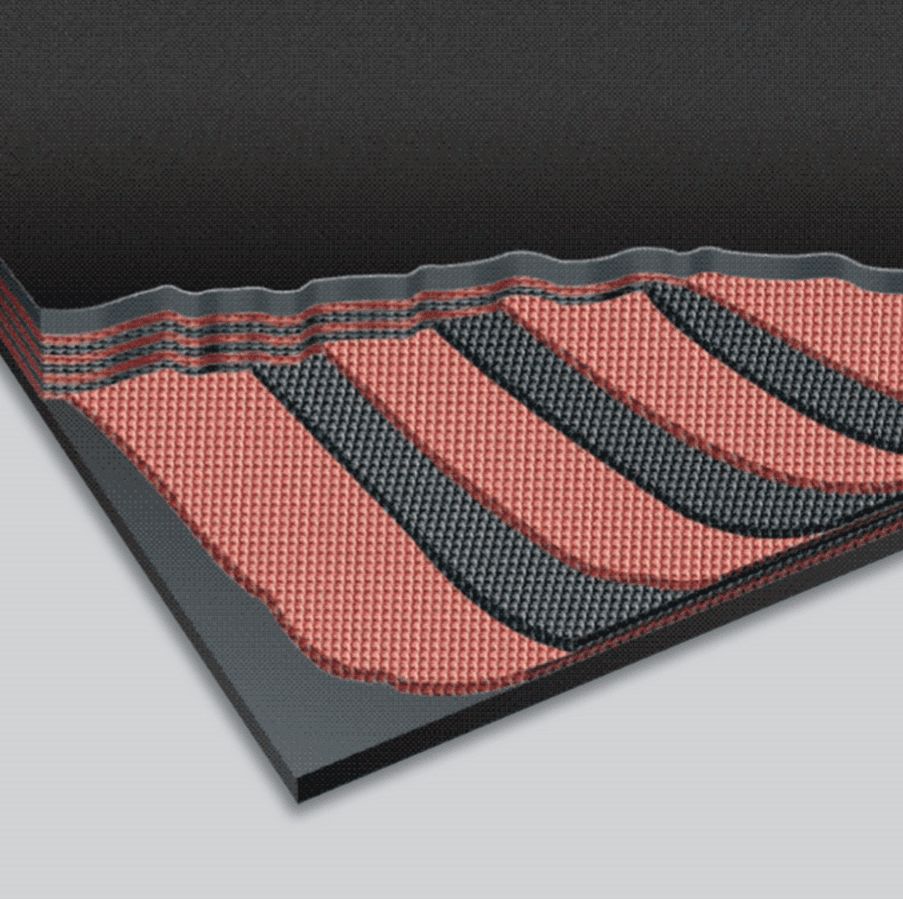

Fabric Conveyor Belting

Our Fabric Conveyor Belts are designed to provide long lasting ability to suit a diverse range of applications.

Our Fabric Conveyor Belts are designed to provide long lasting ability to suit a diverse range of applications.

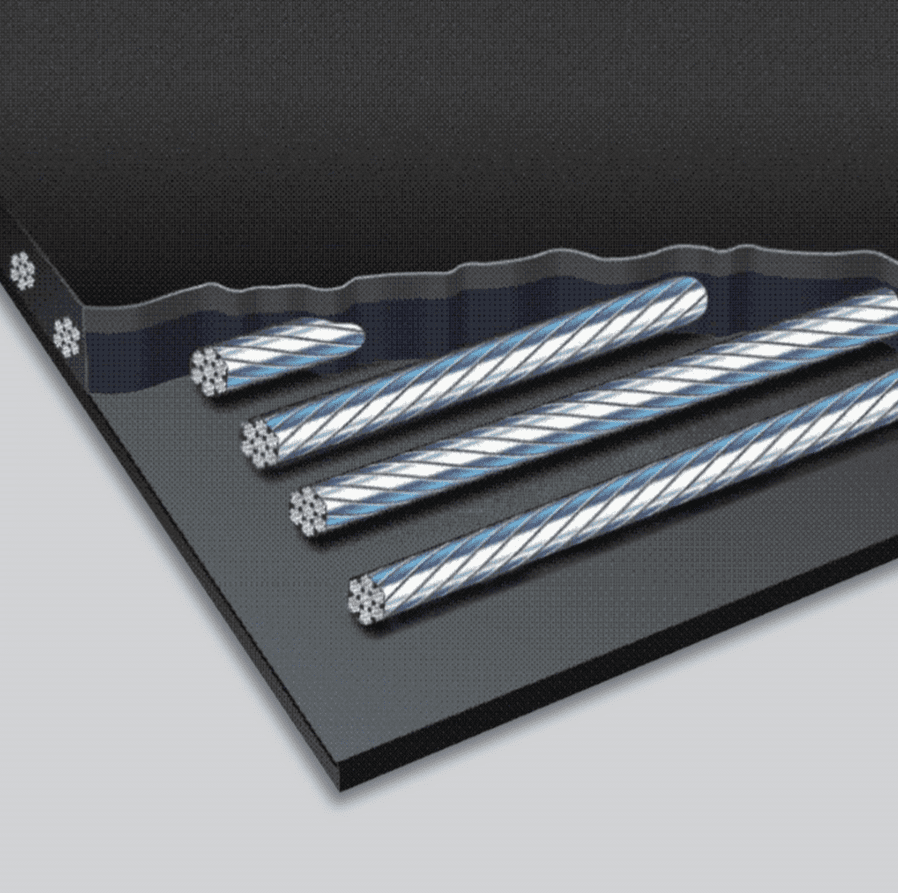

Our Steel Cord Conveyor Belts have been technologically engineered to provide maximum performance and life time.

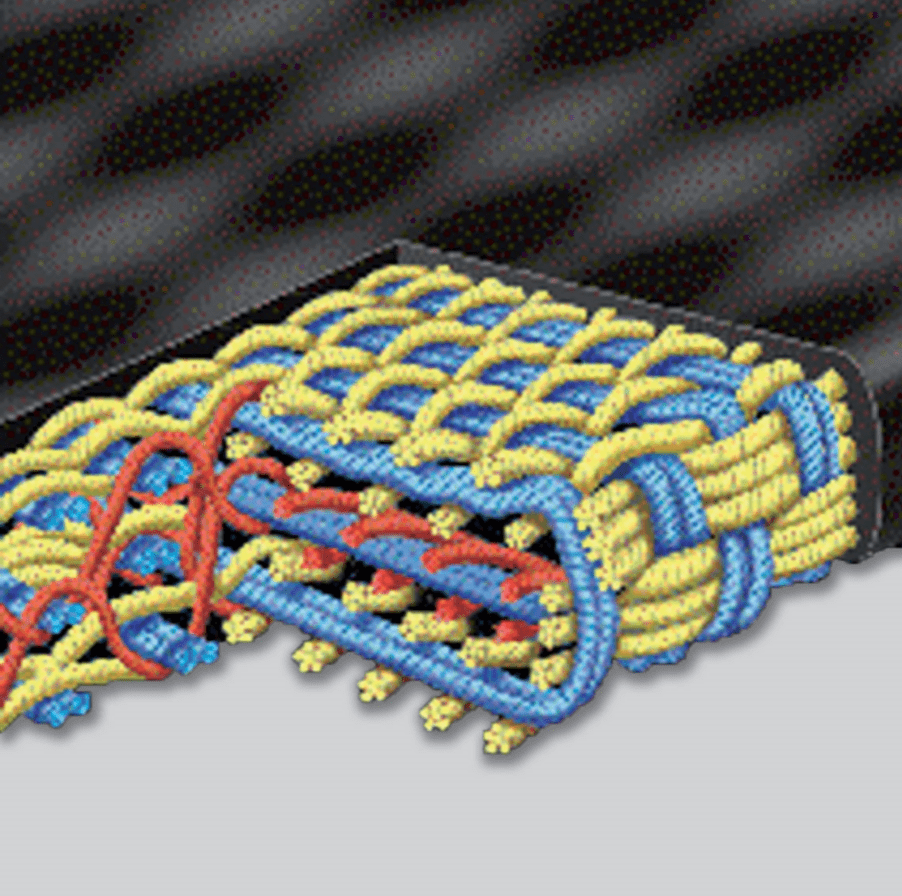

Our Solid Woven Conveyor Belts feature superior rip and abrasion resistance and are available in a range of thicknesses.